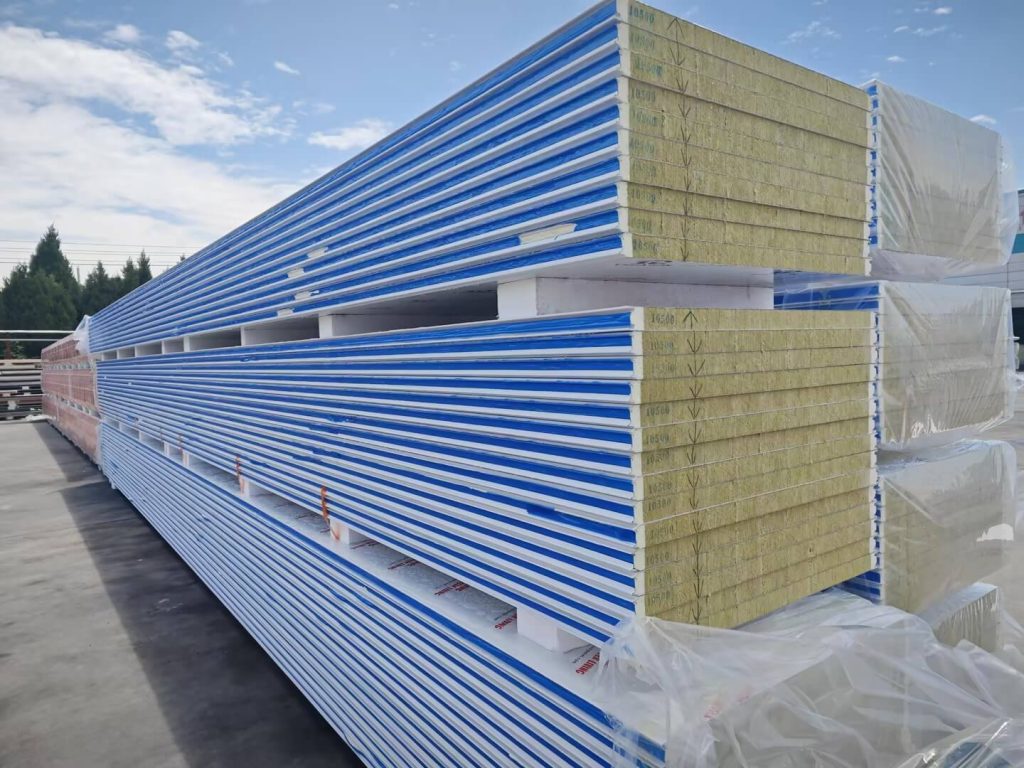

A Comparative Analysis of PIR, XPS, and EPS Sandwich Panels

Among the commonly used insulation materials for sandwich panels, EPS, XPS, and PU are the most prevalent. Let's analyze their characteristics and development trends.

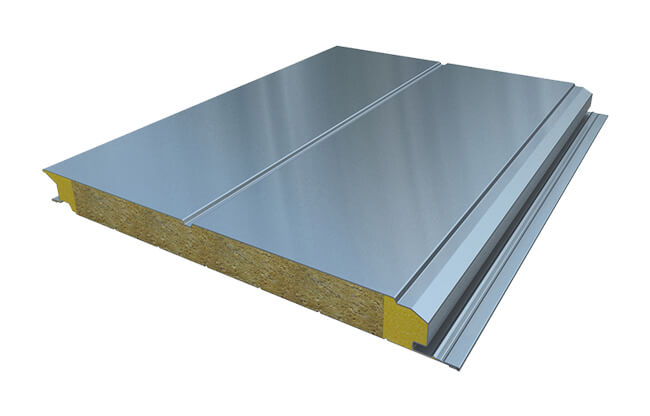

PIR

Polyurethane is a high molecular weight compound containing repeating urethane chains, one of the most important subcategories of polyurethanes. In the context of building insulation, it generally refers to rigid foam, also known as PIR (polyisocyanurate). PIR sandwich panels are currently the best-performing insulation material internationally, surpassing traditional XPS and EPS in various aspects. They offer excellent insulation and strong adhesion, facilitating continuous production and aesthetically pleasing molding. However, the main drawback is their higher cost.

EPS

Expandable polystyrene is a thermoplastic material known for its low cost and decent insulation properties. However, its flame retardancy is poor, and its bonding performance is average.

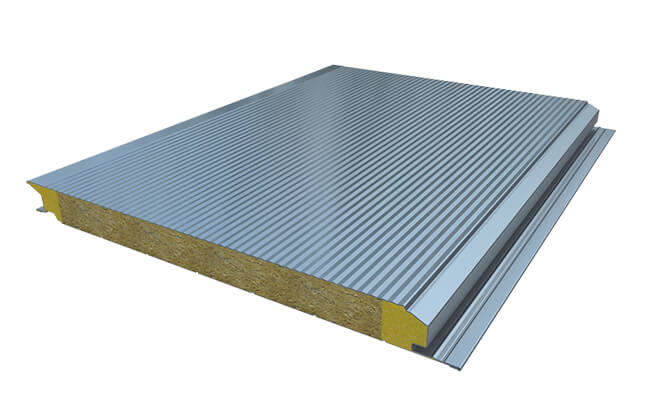

XPS

also known as extruded polystyrene foam board, is created by re-melting waste polystyrene granules and injecting foaming agents like Freon during a high-temperature, high-pressure extrusion process. This forms a cellular structure, providing decent insulation. As a form of polystyrene waste recycling, it is environmentally friendly. Its notable advantages include moderate cost, excellent waterproofing, high strength, and stable molding, making it suitable even for constructing aircraft runways. In recent years, it has been widely used in exterior wall insulation. However, its drawbacks include poor bonding performance and average insulation.

Comparison of the performance of the three materials

| Unit | PIR Sandwich Panel | XPS Sandwich Panel | EPS Sandwich Panel | |

| Thermal Conductivity | W/m·k | ≤0.022 | ≤0.029 | ≤0.042 |

| Compressive Strength | KPA | ≥150 | ≥200 | ≥69 |

| Max. Temperature | °C | 120 | 95 | 70 |

| Flame Retardancy | Self-extinguishing | Melts and drips when exposed to fire | Melts and drips when exposed to fire | |

| Fire Rating | B1 | B2 | ||

| Density | KG/m³ | 30-40 | 40 | 12-20 |

| Bonding Strength | MPA | >0.15 | >0.25 | >0.1 |

| Sealing/Water Resistance | 90% closed cells, 100% skin closed cells, all gaps sealed | Gaps and cavities, air and water easily penetrate cracks and cavities | Gaps and cavities, air and water easily penetrate cracks and cavities | |

| Environmental Performance | No fluorine-containing foaming agents | Mostly uses Freon, which is harmful to the ozone layer | Mostly uses Freon, which is harmful to the ozone layer |

In conclusion, PIR sandwich panels demonstrate immense potential in the thermal insulation field due to their exceptional overall performance. While they come at a higher cost, their superior fire resistance, insulation effectiveness, bonding strength, and environmental friendliness position them as a preferred material for future energy-efficient construction.

Of course, Henan Tseason Panel Co., Ltd. also offers EPS and XPS sandwich panels to cater to diverse customer needs and budgets. We are committed to providing comprehensive insulation solutions to help our clients achieve green building and energy conservation goals. With continuous technological advancements and decreasing production costs, PIR, EPS, and XPS sandwich panels are all poised to play a more significant role in the construction industry, contributing to a more sustainable future.