Building Smarter: Polyurethane Panels for Walls

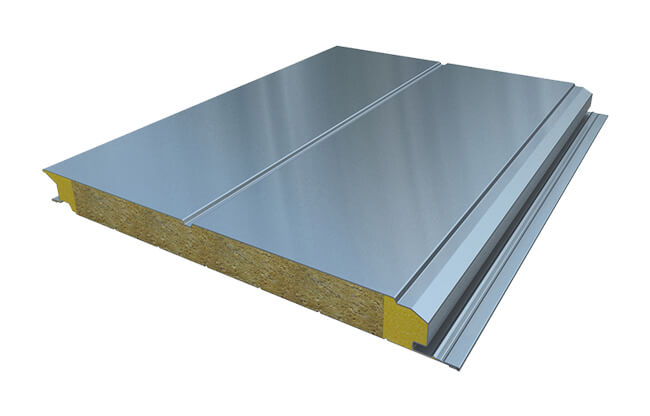

Polyurethane wall panels are very environmentally friendly, easy to install, and energy efficient, making them one of the more popular wall materials today. Place the liner after the moisture barrier is in place. Use nails when installing the liner, but the distance between the nails may need to be controlled at about 200 millimeters to avoid deformation due to temperature changes.

The process of installing polyurethane wall panels

1. Cold storage panel installation: Find the position and line. According to the design drawing requirements, find the height of the elastic line, plane position, and vertical dimensions before installation.

2. How do you install wall panels and identify the embedded parts and holes? If the arrangement meets the requirements of the keel, doors, windows, and vertical position, then the built-in part should check whether the wooden brick or wedge meets the requirements after playing a good line.

3. How do you install wall panels, packaging, and moisture-proof coating? After the entrance inspection, you can place a moisture-proof wood wall when laying the skeleton so the pad between the boards and bricks slides. In addition, two wooden pegs were used for each wooden brick and keel. The keel was loaded but loaded when the board was thick. The wooden keel and wall must be treated with corrosion, and other surfaces must be fireproof.

4. Cold storage board how to install, liner installation in the moisture barrier in place after placing the liner in the liner installation using nails, but the distance between the nails may need to be controlled at about 200 millimeters. To avoid deformation due to temperature changes, it is necessary to ensure a spacing of about 5mm between the spliced panels.

Installation instructions for polyurethane wall panels

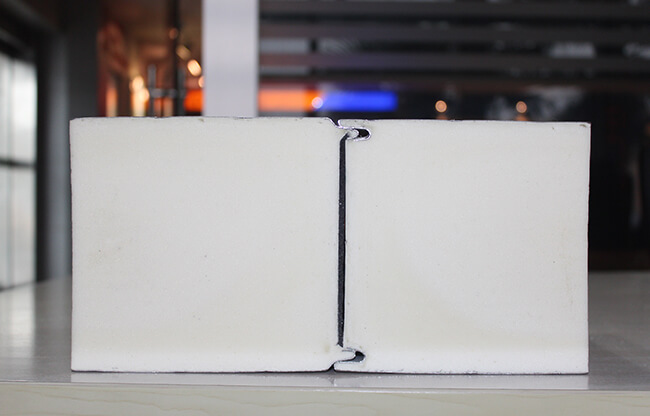

1. The cold storage panel structure must be reserved for holes first and installed from the joints of wall columns.

2. Impurities should be removed to ensure that the wall is clean. Show line doors and windows pop-up assembly line, and check the floor's flatness. According to the wall pop-up ceiling position line design requirements, the concrete should be smooth and have a strength of up to 2.5MPa.

3. Adhesive is applied to the top and side joints of the cold storage board. The coating is more than 5mm thick.

4. When installing the patch, cut along the horizontal board, fill the vertical cut with cement mortar, and coat it with Adhesive.

5. When fixing the polyurethane wall panel, finish the board first and then add the board.

As a manufacturer of polyurethane composite panels, Tseason advises that when erecting walls, a tamper-evident rod should press the sides to ensure the verticality and flatness are correctly adjusted. This helps to create smooth, straight joints with gaps not exceeding 5mm.