Choosing the Right Materials for Cold Storage Installation

In addition to heat insulation and moistureproof materials, cold storage design materials, such as bricks, stones, cement, concrete, mortar, steel, and polyurethane cold storage panels, are used in relatively large quantities. Most of the building materials used in cold storage are in a low-temperature and humid environment, so the cold storage design materials used have special requirements for frost and water resistance. As a leading manufacturer of high-end polyurethane (PU) sandwich panels for cold storage applications, including wall, ceiling, and roofing panels, Tseason is pleased to share valuable insights on material selection for optimal cold storage design and installation.

Brick or stone

Brick or stone used for cold storage exterior walls requires MU7.5 and a frost resistance level of 25; if used for low-temperature storage lining walls or internal partition walls, the requirements are MU10 and a frost resistance level of 35.

Ordinary silicate cement has better frost resistance, so it should be given priority in the structural parts of low-temperature warehouses and freezing rooms in cold storage. This is because slag cement also has better frost resistance.

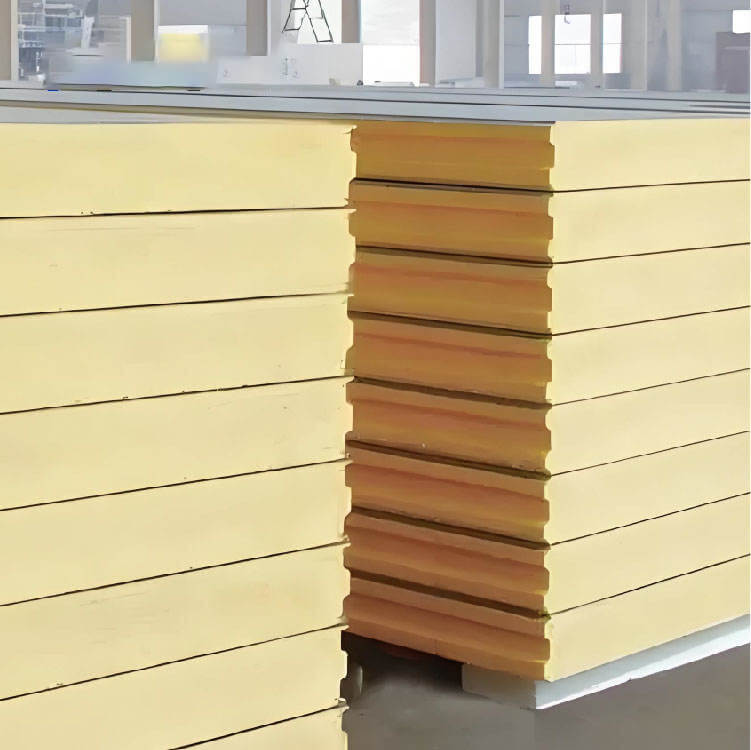

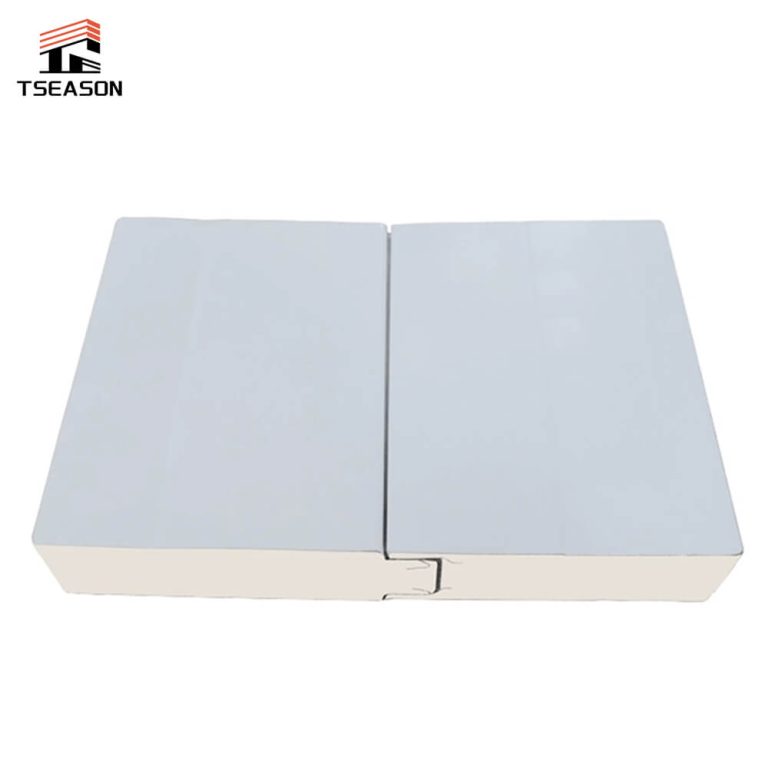

Cold room panel

Tseason cam lock cold room panels are constructed with rigid polyurethane (PU) insulation, a material renowned for its exceptional thermal performance. With a thermal conductivity as low as 0.018 to 0.023 W/(m·K), PU insulation surpasses traditional materials like EPS, significantly reducing heat transfer and enhancing energy efficiency in cold storage facilities. This superior insulation allows for thinner panel construction, maximizing usable space while maintaining optimal temperature control.

Additionally, Tseason cam lock cold room panels demonstrate remarkable dimensional stability, resisting deformation and cracking even in demanding cold storage environments. The closed-cell structure of PU insulation provides inherent moisture resistance, preventing water absorption and maintaining consistent thermal performance over time. Furthermore, Tseason's PU panels offer excellent fire resistance, meeting stringent safety standards and effectively hindering fire spread. Choose Tseason cam lock cold room panels for unparalleled insulation, durability, and safety in your cold storage projects.

Cold storage design specification

The general cold room concrete grade should not be less than C20, the water-cement ratio should not be greater than 0.6, the freezing room concrete grade should not be less than C30, and the water-cement ratio should not exceed 0.55. Water cement is small, if more than these standards, and will have the following phenomena: poor molding, inaccessible to dense, porous, water-filled, and more. The larger the water-cement ratio, the more voids in the concrete. This will only increase the difficulty of construction and thus reduce the construction time. Test results prove the best water-cement ratio of 0.55 ~ 0.6 of the concrete frost resistance performance.

Cold storage facilities operate in demanding low-temperature environments, enduring continuous freezing and thawing cycles that can easily damage building structures. To mitigate this, the design of cold storage facilities must prioritize materials with exceptional freeze-thaw resistance. By selecting materials that can withstand these harsh conditions, operators can avoid costly repairs and maintenance, ensuring their cold storage operations' long-term efficiency and reliability.