Cold Room Panels Prioritize Quality Over Price

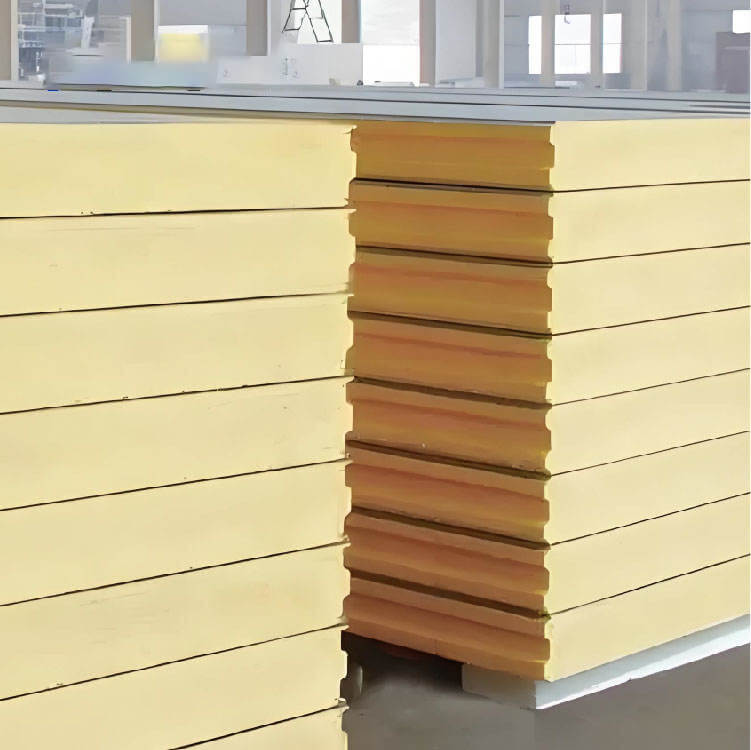

Polyurethane (PU) cold room panels have become the dominant choice in the cold storage industry, and for good reason. The quality of PU cold room panels directly determines a cold storage facility's overall effectiveness and efficiency. Therefore, careful consideration and due diligence are crucial when selecting a PU cold room panel supplier.

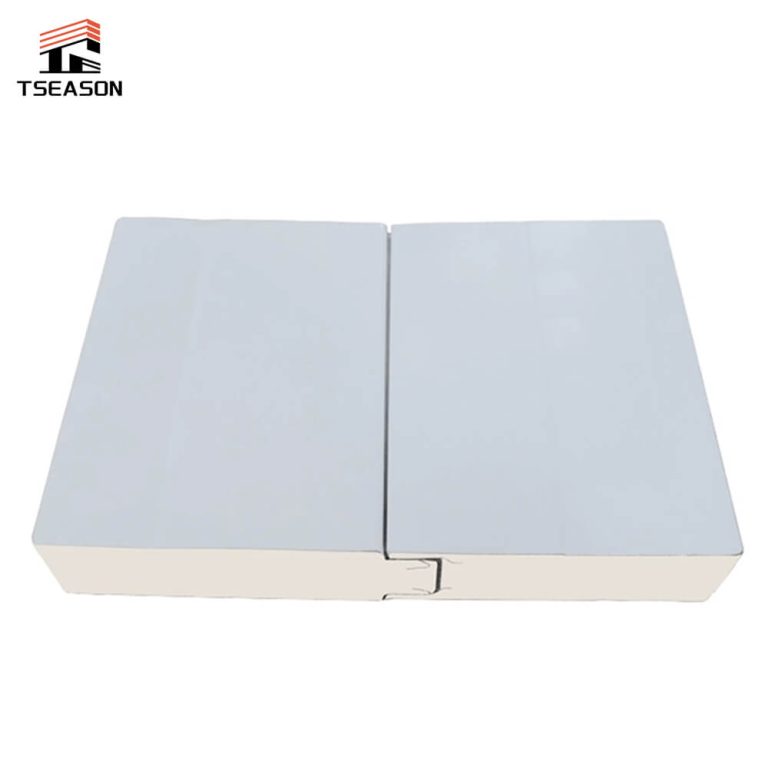

When choosing a PU cold room panel supplier, Tseason emphasizes that insulation performance, dimensional stability, and service life are crucial factors that cannot be easily discerned. The difference between a good and bad panel can be subtle yet significant, impacting the long-term performance of your cold storage facility. Prioritize quality over price, as opting for inferior panels solely based on cost may lead to costly repairs and replacements down the line. Invest in high-quality PU cold room panels from reputable suppliers like Tseason to ensure optimal insulation, longevity, and overall value for your investment.

Polyurethane spray coating is used for cold storage insulation, the raw materials used by various families; spraying construction technology is the same, made of foam in appearance is also very similar, but the use of different raw materials will be caused to a large extent by the performance of the final product between the differences, and even the use of some poor quality raw materials will make the original purpose of heat preservation can not be embodied. To make the product achieve the optimal thermal insulation and energy-saving effect so that the long-term interests of cold storage investors can be maximized, Tseason has taken strict and effective control measures on product quality, which are introduced here as follows to facilitate the selection of thermal insulation materials for cold storage reference:

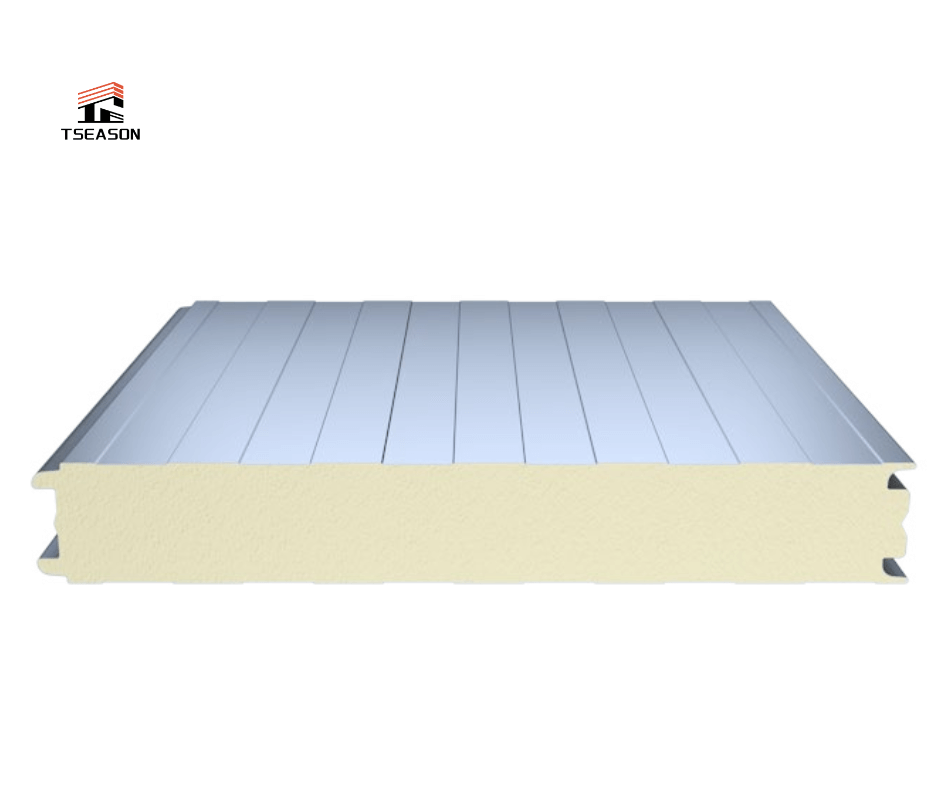

Thermal insulation performance

The first requirement of polyurethane materials used in cold storage is thermal insulation performance, and whether thermal insulation performance is good or bad in actual put into use before it is impossible to observe with the naked eye, to the point of observing the difference between the high and low power consumption when it is already too late.

Tseason through a large number of formula tests and performance tests in the selection of materials to carry out strict control to achieve this purpose:

- Use structural amine ether to reduce thermal conductivity and improve thermal insulation effect;

- All kinds of raw materials and formulas try to reduce the water content to avoid the deterioration of thermal insulation performance caused by water foaming;

- The main material polyether: Tseason selects the products after strict post-processing; compared with the polyether without post-processing of some manufacturers, the foam of Tseason has a high degree of uniformity of the bubble holes, the bubble holes are thinner in the wall, and the heat preservation performance is better than the ordinary foam with thick wall and big holes;

- The use of high efficient odorless amine catalyst effectively adjusts the balance of the foaming-gelation reaction, making the skin between sprayed layers thinner, which is conducive to the manifestation of heat preservation performance;

- Tseason does not use standard polyester polyol, which has a controversial influence on heat preservation performance.

Foam size stability

Polyurethane foam material in drastic temperature changes or long-term at lower temperatures will appear in size changes (generally shrinkage). Size changes are often embodied in the wall of the foam cracking or falling off, and these will inevitably affect the regular use of cold storage and, when severe, may cause significant economic losses. In addition to the performance test of regular good simulation, Tseason pays more attention to the control in the selection of high-quality materials:

- Tseason employs specialized polyether compounds to create a robust, three-dimensional network structure within the foam, significantly enhancing its low-temperature resistance compared to the standard 4110 polyethers used in spray coatings.

- Using functional crosslinking agents further improves the dimensional stability of Tseason's foam. Our polyether undergoes thorough reaction with strong alkali catalysts, ensuring a high reaction rate and complete bonding with black materials, unlike weakly catalyzed polyethers that often result in poor dimensional stability.

- Some manufacturers sacrifice insulation performance by adding open-cell components to stabilize foam size, which is unethical. Tseason maintains high closed-cell rates, ensuring optimal insulation while achieving dimensional stability through superior materials and processes.

The service life of the foam

In addition to the essential performance of the foam at the beginning, the deterioration of the foam performance is also a significant indicator. In the material preparation, the use of certain polyester materials on the surface of the foam has a better toughness and impact resistance, but its use after some time will become brittle and no longer have impact resistance collision. In addition, some polyester structure foam hydrolysis resistance is poor, which will also affect the service life of the foam. Tseason adopts the structure of the polyether, the initial period of the slightly brittle, but generally a few days after the brittleness disappears, and then it can be a long period to maintain a stable performance. Tseason adopts a polyether structure.

Flame retardant:

As a leading fridge panel wall manufacturer, Tseason recognizes the importance of balancing fire safety and thermal performance in polyurethane (PU) insulation. While flame retardancy is crucial, overemphasizing it can compromise the essential insulation properties required for efficient cold storage.

Tseason's PU fridge panels strike an optimal balance by utilizing advanced flame retardant technologies without sacrificing thermal efficiency. Our panels meet stringent B1 fire proof standards while ensuring minimal energy loss, contributing to lower operating costs and a more sustainable cold storage solution. Choose Tseason for fridge panel walls that prioritize both safety and performance.