Cold Storage Efficiency: How to Choose the Best Insulation Cold Room Panels

At present, cold storage has been an essential part of the logistics industry, involving people's lives in various fields, food, dairy products, meat, aquatic products, poultry, fruits and vegetables, beverages, flowers, greenery, tea, pharmaceuticals, chemical raw materials, and other semi-finished products and finished products storage has an important role.

The cold storage installation project is an essential component of the cold room panel; the cold room panel is directly related to the cold storage refrigeration effect, and the use of a time the coldroom panel should be how to choose.

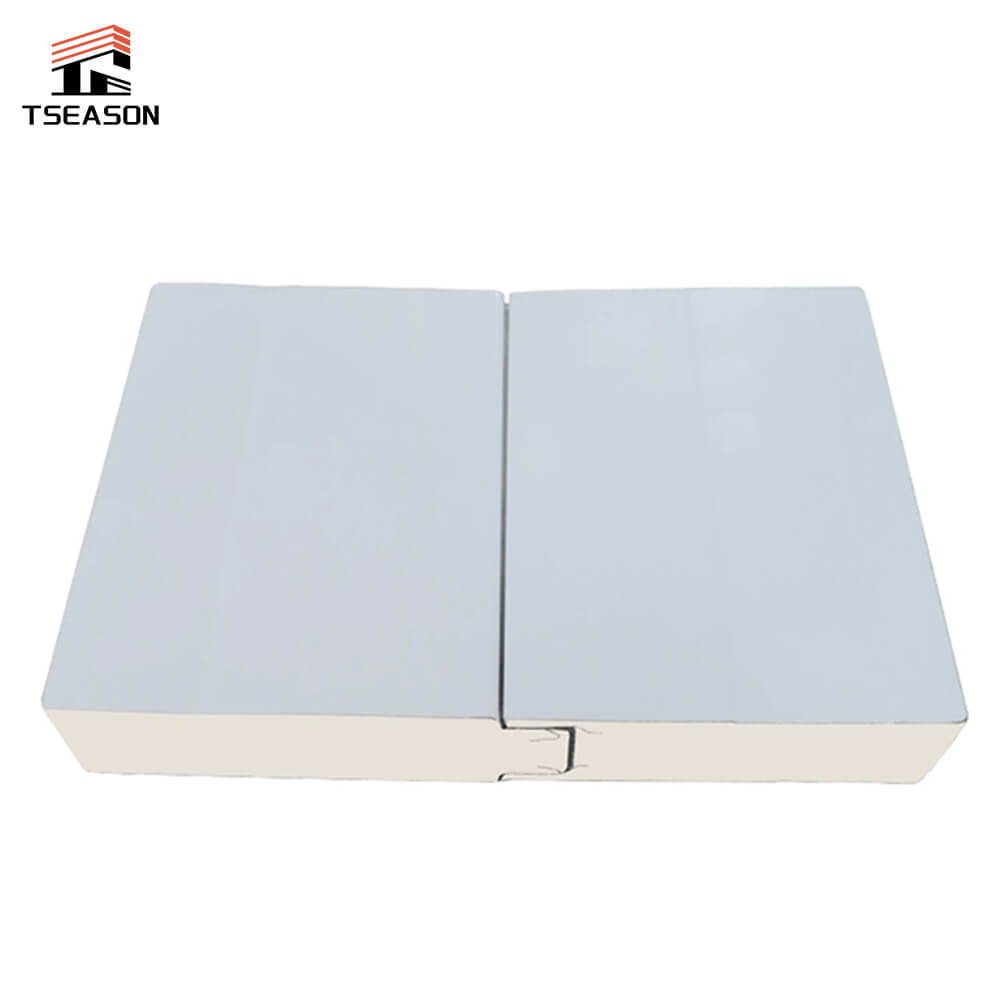

1. Cold Room Panel Classification

Coldroom Panel, according to material classification, generally has polyethylene cold storage board and polyphenylene cold storage board; in addition to these two materials in addition to polyurethane cold storage board, this plate, compared to the first two performances, is better than polyphenylene cold storage board due to the lack of density of the thermal insulation material, generally used in special equipment, polyethylene cold storage board thermal insulation effect is better than polypropylene. Of course, the best comprehensive conditions are the polyurethane cold storage board.

2. Cold Room Panel specifications

The effectiveness of a cold room unit is significantly influenced by the dimensions and thickness of its panels. Standard thicknesses include 60, 75, 100, 120, 150, and 180mm, with a conventional width of 960mm and heights ranging from 2 to 10 meters. Customization options cater to unique requirements, although manufacturers typically have pre-determined dimensions. Choosing between high-, medium-, or low-temperature storage modules depends on the intended use, balancing insulation performance with construction and operational costs. Recommendations for insulation thickness vary based on storage temperature requirements, emphasizing the correlation between panel thickness and insulation efficacy.

3. Cold Room Panel Protection Materials are Mainly The Following

Embossed aluminum plate, stainless steel plate, color zinc steel plate, salted steel plate, and standard floor plate: 1.0mm galvanized sheet, of which the embossed aluminum and stainless steel plate are used more. For the choice of cold storage board, one should pay attention to the degree of sparseness of the library board and the thickness of the protective material steel plate; the regular manufacturers of steel plate thickness is generally more than 0.4mm.

4. Polyurethane Cold Room Panel Advantage

Polyurethane cold storage board with lightweight polyurethane as the sandwich material of the cold storage board; polyurethane advantage lies in the heat insulation performance good polyurethane cold storage of the outside of the PVC color steel plate and stainless steel plate components and become, can prevent the cold storage board because of the temperature difference between the inside and outside of the temperature caused by the temperature of the conduction, to make the cold storage of energy-saving, improve the efficiency of the work of the cold storage. Cold storage plate has corrosion resistance, anti-aging, flame retardant, non-toxic, lightweight, inexpensive, strong pressure resistance, safe and reliable, beautiful appearance, easy to operate, long service life, hygiene, and other characteristics.