Everything You Need to Know About Polyurethane Freezer Panel Specifications and Costs

For the construction of cold storage rooms, more and more people have chosen to use polyurethane freezer panels. What is the reason for this? Polyurethane freezer panels have cold storage, preservation of freshness, and other efficacy. What is the freezer panel price, and what are the factors related to it?

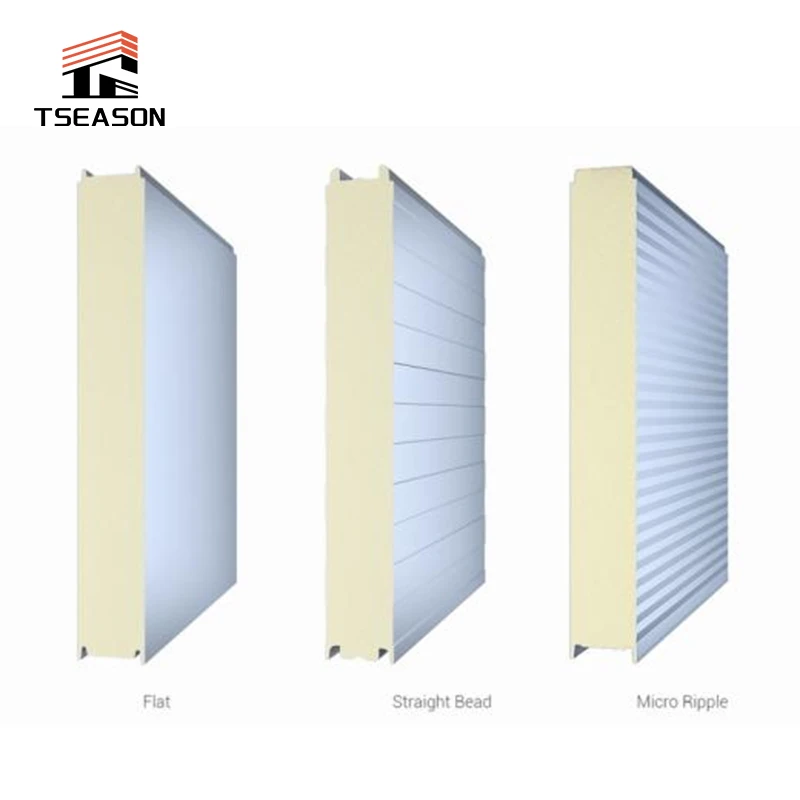

Freezer Panels Metal Layers

Polyurethane plate upper and lower steel plate polyurethane cold storage plate has two layers of steel plate; the price of the upper and lower steel plate by thickness, coating, manufacturers, plating, and other factors, the higher the price of the upper and lower steel plate requirements will naturally be higher. Polyurethane freezer panels often choose color steel plate, stainless steel plate, PVC and other materials, steel plate and rigid foam polyurethane inner material composite, steel plate partition can prevent the freezer panel because of the temperature difference between the inside and outside of the temperature caused by the conduction of the temperature, to make the cold storage is more energy efficient, improve the efficiency of the work of the cold storage. Tseason use of the top and bottom of the steel plate of origin is from Guanzhou, Shanghai Baosteel, and other big panel brands. The thickness is generally 0.3-0.5mm. Typically, 0.3-0.5mm thick, 0.5mm is the more commonly used thickness, the width is generally 1000mm and 1200mm, the brand volume compared to the market ordinary volume service life in 10-15 years, more muscular endurance. The coating used is PE coating, SMP coating, HDP coating, PVDF coating, etc., and the coating is hot-dip galvanized and aluminized zinc.

The Freezer Panels Flame Retardant Process

The flame retardant grade and raw material polyurethane freezer panel is divided into B1, B2, and B3 three grades; the amount of black material is the crucial factor depending on the flame retardant grade of polyurethane freezer panel. The more black material, the higher the fire rating of the polyurethane freezer panel; on the contrary, the lower the flame retardant grade of the polyurethane freezer panel. The price of different flame retardant grades is also different; the higher the flame retardant grade, the higher the price. Tseason PUR production line in terms of raw materials and process output ratio, by six copies of the online world advanced automatic operation(SlEMNS)mixed casting technology, for the first time in China to realize multi-component online continuous foaming success. It can complete the online mixing process and adjust the formula freely according to the environmental conditions and mixing devices; the raw materials are mixed more evenly, and the foam is more delicate to produce the ordinary high-strength, excellent thermal insulation cold panel. Insulation cold panel. Poly isocyanuric acid ester (Polyisocyanurate), PIR, PIR cold panel manufacturing process is developed by Tianfonisocyanate by adding excess isocyanate index, introduction offering structure and higher compounds, the formation of more dense cross-linked polyisocyanurate( PlR), from the internal rigid foam is more stable, can use time placed up to 160 ℃

The Thickness of The Freezer Panel

Sheet specifications polyurethane freezer panel in the sales process will be customized according to the different needs of customers with other specifications of the cold storage bar; customers need freezer panel width and thickness is different, and the price is different, the higher the demand for the price is also higher. Tseason for example, polyurethane freezer panel width is generally 1130mm, thin thickness of 100mm, 125mm, 150mm, 175mm, 200mm, etc., the higher the width and thickness, the higher the price.

Other Reasons

Workforce, land force, transportation In addition, the price factors affecting polyurethane freezer panels, factory production consumed by the cost of workforce and land cost, as well as transportation costs, etc., will more or less affect the price fluctuations of polyurethane freezer panels. Quality chemical raw materials and process by Tianfon determines its products with an intense flame through the fire, smoke, toxic, corrosive foam small unique quality; compared with ordinary PUR rigid polyurethane foam, it has a fierce flame through the fire, smoke, toxic, corrosive foam small unique quality, Compared with ordinary PUR rigid polyurethane foam, it has high thermal stability, excellent flame retardancy, low smoke emission and so on.