Factors to Consider When Choosing a Sandwich Panel Manufacturer: Ensuring Your Project’s Success

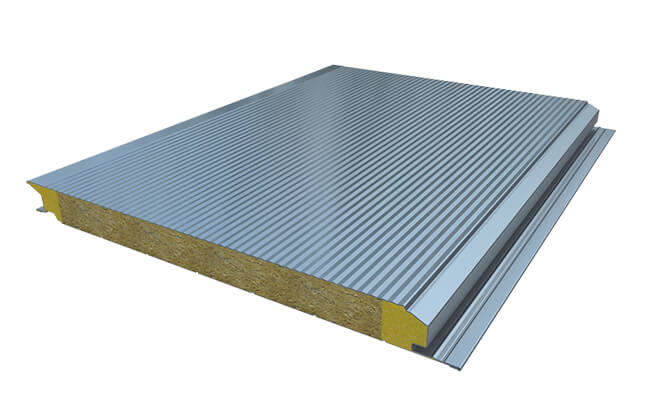

In the sandwich panel manufacturing industry, selecting the proper manufacturer is crucial for the success of your project. High-quality sandwich panels enhance building performance and reduce long-term maintenance costs. Here are the key factors to consider when choosing a sandwich panel manufacturer:

Product Quality and Certifications:

The quality of sandwich panels directly impacts the building's thermal insulation, sound insulation, fire resistance, and other properties. Choose a manufacturer with comprehensive quality management system certifications to ensure their products meet international or national standards. Reputable brands like Tseason have obtained multiple authoritative certifications, including ISO9001 (Quality Management System), ISO14001 (Environmental Management System), OHSAS18001 (Occupational Health and Safety Management System), FM Approval (Fire Resistance Certification), and CE marking (European Conformity), guaranteeing reliable product quality, stable performance, and adherence to stringent safety and environmental standards.

Production Capacity and Experience:

A reliable sandwich panel supplier should have the capacity and experience to meet your project's demands. Tseason, with over 30 years of experience in the industry, boasts state-of-the-art PUMA and OMS production lines, enabling an annual production capacity of 5 million square meters of sandwich panels and 3000 sets of various integrated houses. This extensive experience and large-scale production capacity ensure that Tseason can handle projects of any size while maintaining consistent quality and timely delivery.

Customization Capabilities and Technological Advantages:

Each project has unique requirements, making a manufacturer's customization capabilities crucial. Leading PUF panel manufacturers like Tseason invest heavily in research and development, utilizing cutting-edge technologies and advanced production processes. Tseason's in-house capabilities ensure that they can deliver customized PUF panel solutions that meet the specific needs of each project:

- Self-developed IBIM system: Streamlines design and construction processes for optimized efficiency.

- Class-A design institute: Provides tailored architectural solutions for unique project requirements.

- Dedicated building materials laboratory: Ensures rigorous testing and quality control of PUF panels and continuous innovation in materials and production techniques.

- Additionally, Tseason's exclusive partnerships as the general agent for core raw material brands guarantee the highest quality materials and consistent performance for their PUF panels.

Comprehensive After-Sales Service and Support

A reputable PUF panel supplier should offer more than just high-quality products; they should also provide comprehensive after-sales service and support. Tseason stands out in this regard, offering a complete after-sales system that includes:

- Product traceability: Ensuring the origin and quality of raw materials used in PUF panels.

- Rigorous testing and certification: Subjecting their products to various stringent tests and certifications to meet or exceed industry standards.

- Professional installation services: Provide expert engineers or construction teams with on-site installation, ensuring proper handling and optimal performance of their PUF panels.

- Factory quality inspection: Thorough quality checks are conducted before shipment to guarantee that every panel meets Tseason's high standards.

Selecting the proper sandwich panel manufacturer requires careful consideration of multiple factors. In addition to the above points, you can assess the manufacturer's technological innovation capabilities, research and development investments, and employee qualifications. By conducting a thorough evaluation, you can choose a reputable, strong, and well-serviced manufacturer, laying a solid foundation for your project's success.