Handmade vs. Mechanical: A Comparative Guide to Cleanroom Panel Production

The production process:

- Handmade cleanroom wall panels are also known as manual operation production; mechanism cleanroom panels are machine production.

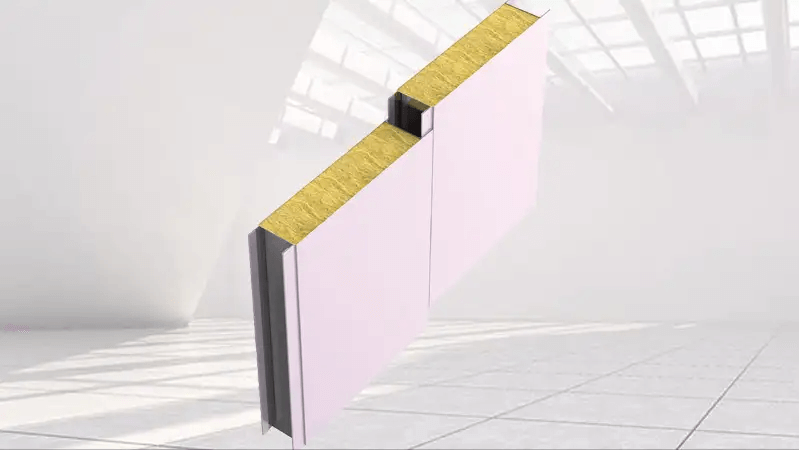

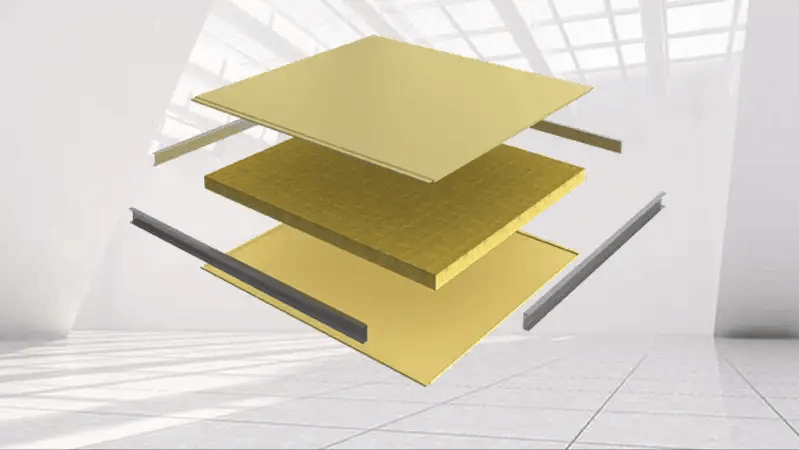

- Handmade cleanroom wall panels can be a composite of a variety of core materials, such as magnesium glass + rock wool (gypsum + rock wool, magnesium glass + aluminum honeycomb, gypsum + aluminum honeycomb, etc. can be a composite of two core materials.

- Mechanism cleanroom panels generally can only be a composite of core material, such as pure rock wool purification board (Class A fire, the most commonly used), silica rock purification board (Class B1 fire, lightweight, low thermal conductivity), magnesium sulfur oxide purification board (Class A fire, used for load-bearing ceiling panels, high strength), aluminum honeycomb purification board (Class B1 fire, lightweight, high-temperature stability is better) and so on.

The production board type

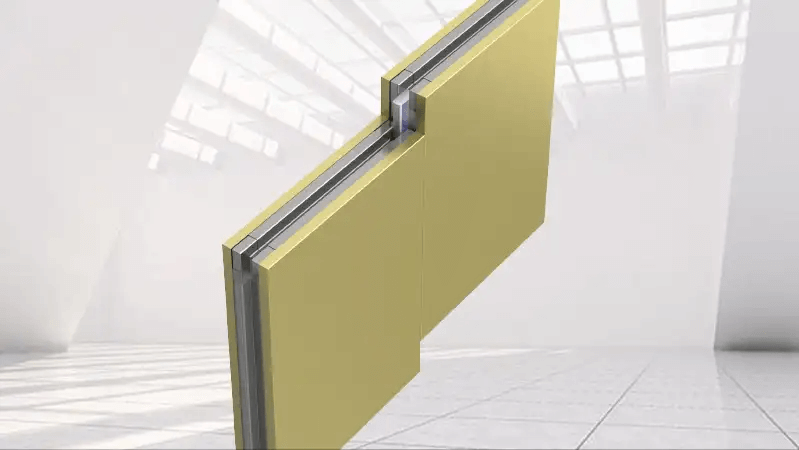

- With handmade panels surrounded by a galvanized keel, the overall strength of the plate is more significant; you can also use the word concave-convex type and other types of panels.

- The mechanism board is used to seal the edges of the steel belt. It is not as strong as the handmade board, which is the installation mode for the enterprise mouth-type insertion.

The price

Handmade cleanroom wall panels' overall production process and product performance are better than those of cleanroom panels, so the price is higher than that of purification boards.

Production efficiency

- Mechanism cleanroom panel production efficiency is greater than the manual board production efficiency.

- The mechanism of the cleanroom panel's daily output and production speed are higher than the manual one.

The cleanroom wall panel mechanism's most significant advantage over the manual one is its low cost and high production volume.

Ordinary clean environments can use the mechanism of a cleanroom panel, production speed, and short delivery cycle. The mechanism cleanroom panel is for standardized production, and the board width specifications are generally 1150mm and 950mm, which are two types of panels. Both ends of the plate are blocked with steel plates, which are pressed and sealed, mainly for the enterprise mouth plate type. They are easy to insert and fast to install.

If you need to increase the strength of the plate, you can add longitudinal reinforcement. It is suitable for wall panels, and the maximum length is not more than 6 meters. Because of its plate type, it is not recommended for ceilings.

Considering it comprehensively, you can choose the mechanism cleanroom wall panel if the product's performance is not essential. If you have higher requirements for the board, you must consider a handmade cleanroom wall panel.