Physical Properties Affecting Polyurethane Cooler Panels

Compressive Strength

Compressive strength reflects how much stress a material can bear per unit area before it deforms. Polyurethane sandwich panels, composed mainly of rigid foam, may experience shrinkage and deformation during foaming due to internal and external pressure differences. Adding foaming agents can amplify this effect. The panel’s insulation efficiency and load-bearing capacity drop if the foam shrinks. Thus, higher compressive strength helps maintain foam stability, ensuring that polyurethane cooler panels remain strong, durable, and thermally efficient.

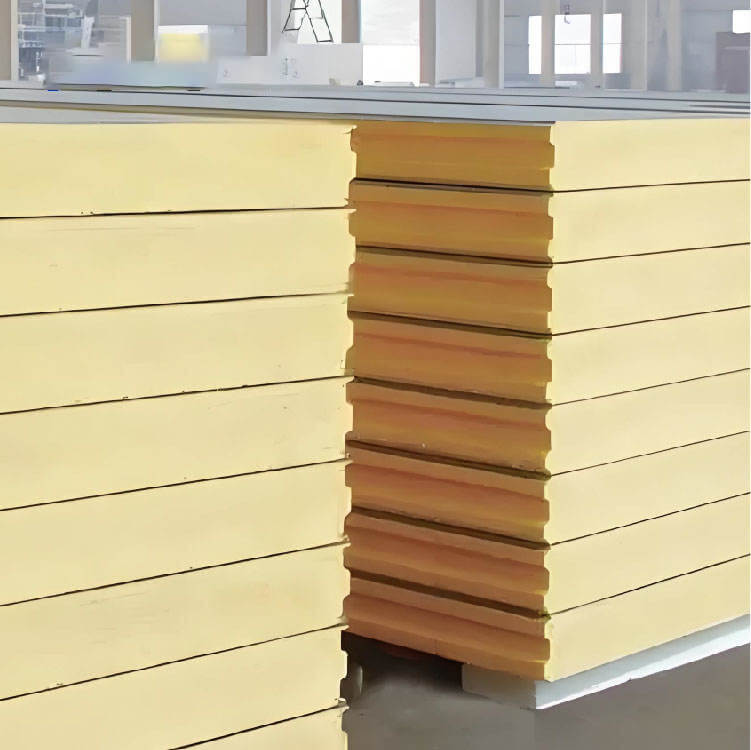

Adhesive Strength

Polyurethane cooler panels comprise a rigid foam core sandwiched between steel coils. These layers are bonded during production using glue or the foam’s adhesive properties. Adhesive strength measures how well the steel and core adhere. Higher adhesive strength improves the overall quality of the panel, contributing to a longer lifespan.

Bending Load-Bearing Capacity

The bending strength of a material shows its resistance to breaking or deforming under pressure. This property is tested by placing a specimen on supports and applying a load in the center. For polyurethane sandwich panels, bending strength is crucial in applications where the material must bear significant weight, such as in structural elements of prefabricated houses. Greater bending strength increases the durability and reliability of the panel.

Tseason's Commitment to Quality

As a leading manufacturer, Tseason focuses on providing top-quality sandwich panels with superior performance. With a "Better Space, Better Living" mission, the company offers reliable polyurethane cold storage panels and solutions. If you're seeking cold storage construction or procurement, Tseason provides quality assurance and innovative approaches to meet your needs.