Polyurethane Edge-Sealed Rockwool and Rock Wool Sandwich Panel: A Comparative Analysis

Polyurethane edge-sealing rockwool sandwich panels, also known as polyurethane side-sealed rockwool sandwich panels, fully utilize the thermal insulation properties of polyurethane and the fireproof performance of rock wool, making them a new type of composite panel that combines thermal insulation and fire resistance.

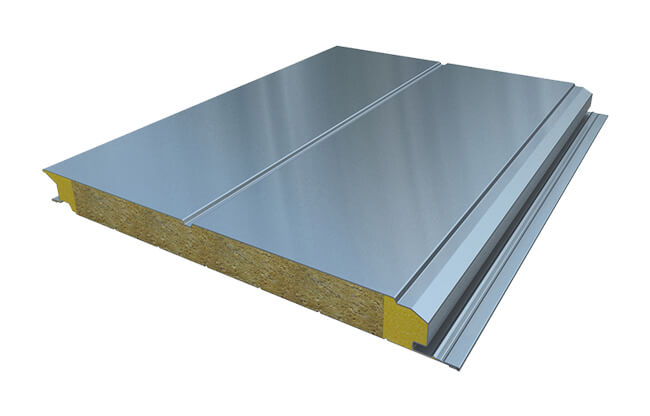

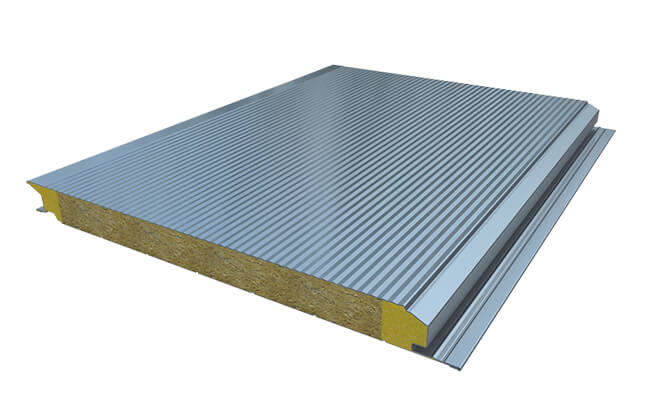

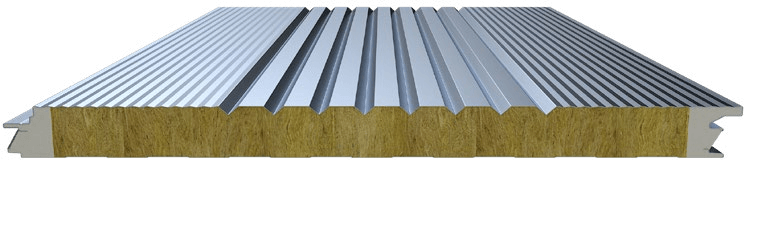

Polyurethane edge-sealed rockwool sandwich panels are made with two layers of high-quality colored coated steel plates or other precisely pressed metal plates as the panels. After being rolled and formed, the rock wool/glass wool is flipped 90 degrees after being cut into strips (so that the fibers are perpendicular to the upper and lower steel plates).

Through high-strength, high-viscosity, and high-fire-resistant adhesives, high-quality rock wool/glass wool is firmly bonded to the metal panels to form beautiful, flat, and rigid building panels. The finished polyurethane edge-sealed rockwool sandwich panels have excellent fireproof, thermal insulation, and environmental protection properties, providing a good choice for industrial building enclosure systems.

The following details the comparative advantages of the new polyurethane side-sealed rock wool sandwich panels over ordinary rock wool panels.

| Feature | Polyurethane Edge-Sealing Rockwool Panel | Ordinary Rockwool Panel |

| Thermal Conductivity | ≤0.025 W/m·k | ≤0.043 W/m·k |

| Compressive Strength | ≥150KPA | ≥100KPA |

| Fire Resistance | Class A non-combustible | Class A non-combustible |

| Density | 80-120KG/㎡ | 40-60KG/㎡ |

| Sealing and Waterproofing | Excellent, overcome water absorption and deliquescence of rock wool | No edge sealing. Water can penetrate and cause deformation |

| Panel Lap | Hidden lap extends service life | Exposed nail installation: nails can corrode |

| Environmental Performance | Prevents Rock wool exposure | Rock wool can be exposed |

This new rock wool sandwich panel type is divided into roof and wall panels. It can be widely used in the roofs, exterior walls, and interior partitions of industrial and civil buildings with fireproof, soundproof, and thermal insulation requirements, especially in projects with high fire protection requirements.

Advantages of Polyurethane Edge-Sealing Rockwool Sandwich Panels:

In terms of material, polyurethane edge-sealed rock wool panels have two more polyurethane edge seals than ordinary-colored steel rock wool sandwich panels. In terms of performance, polyurethane has better bending resistance and load-bearing performance, so polyurethane edge-sealed rock wool panels are firmer and less prone to delamination than ordinary colored steel sandwich panels and have better thermal insulation performance.

Excellent fireproof performance:

Polyurethane edge-sealed rockwool sandwich panels are fireproof due to the raw materials, production process, and formula.

Good thermal insulation and heat preservation:

The thermal insulation and heat preservation performance of polyurethane double-sided edge-sealed rock wool sandwich panels is calculated based on the thermal conductivity of Rock wool λ=0.043 W / m. K and the thickness of the Rockwool core material according to the response ratio.

Significant sound insulation and sound absorption results:

Polyurethane double-sided edge-sealed rockwool sandwich panels significantly attenuate noise transmission, making them especially suitable for places where specific flights pass. In addition, rockwool roof panels significantly weaken the impact of rainwater and hail on buildings' roof steel plates and the resulting indoor noise.

Polyurethane edge-sealed rock wool panels are internationally recognized as fireproof and thermal insulation panels for building enclosures. They have low thermal conductivity, good load-bearing capacity, high bending strength, are water-resistant, non-corrosive, non-worm-eaten, and have good fire resistance and a wide temperature range. Utilizing the physical properties and unique formula of polyurethane, polyurethane foaming