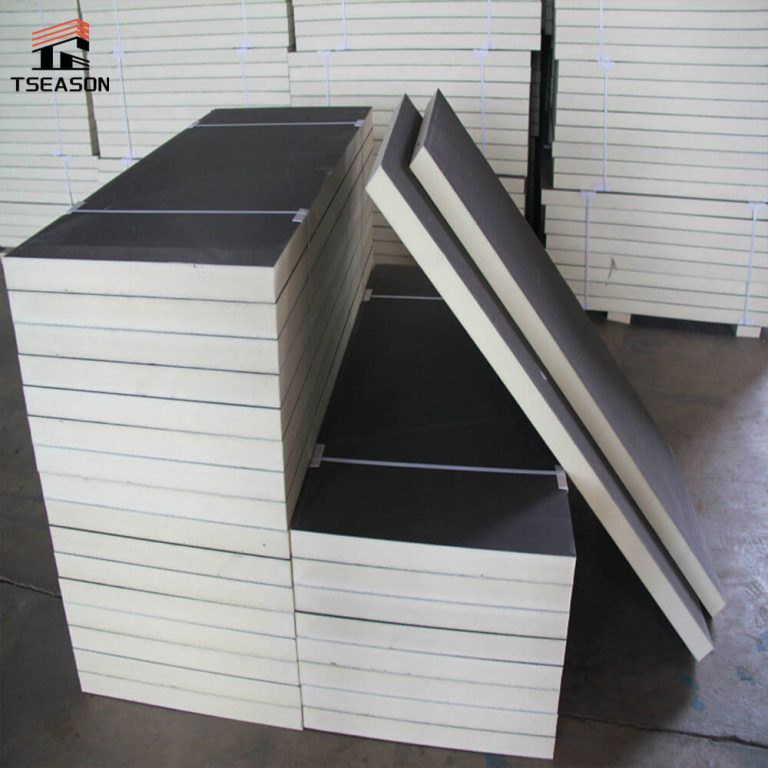

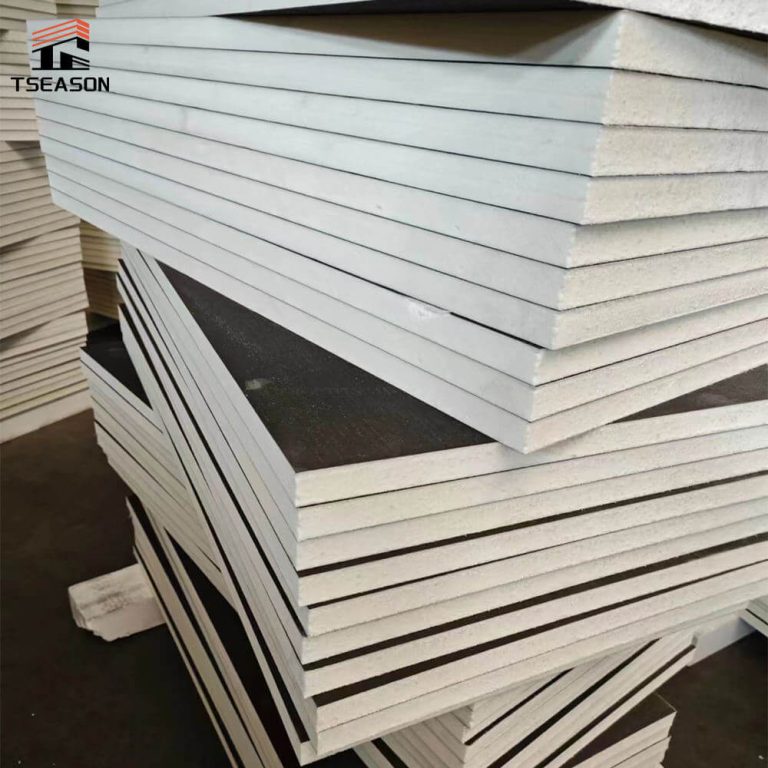

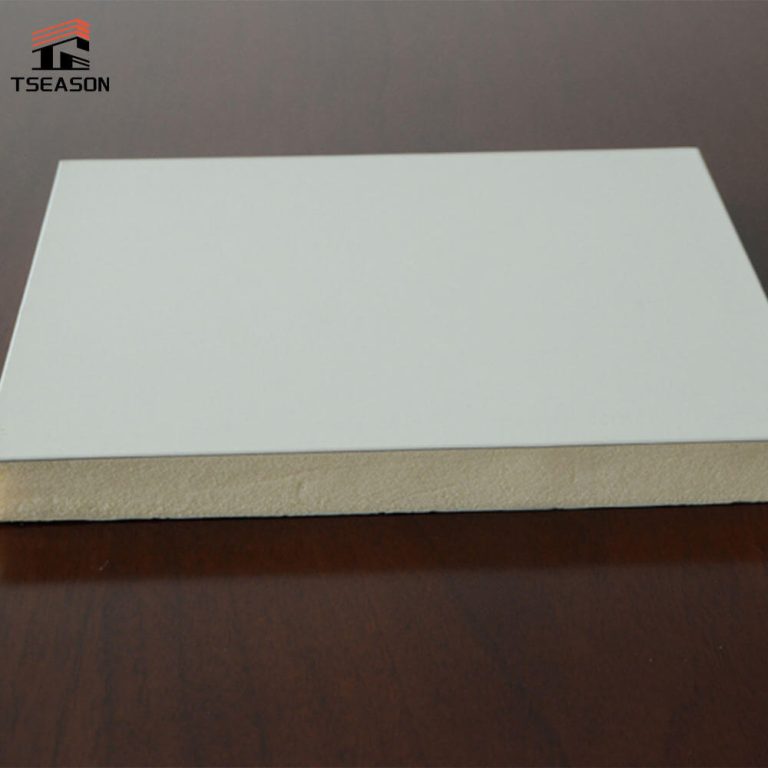

The PIR insulation board utilizes advanced polyurethane rigid foam, a top-tier building material for energy efficiency. Manufactured using a continuous foaming production line, this process combines dual-component polyurethane liquids to create foam with precise thickness and strength. A composite layer of fireproof mortar is directly applied to the surface during production, resulting in a 3-layer enhanced thermal insulation and fireproof composite panel. This innovative design ensures superior energy-saving performance while offering enhanced fire resistance.

The rigid foam PIR insulation board is produced by a continuous production line, the interface layer is made of glass fiber cement-based reinforced coil, and the high flame retardant material is injected in the middle.

| Density | 42 kg/m³ | |

| Water Absorption | 2% | |

| Heat Conductivity Coefficient | 0.022 W/m .k | |

| Compressive Strength [deformation 10%] | 167 kPa | |

| Oxygen index | 30.7% | |

| Heat Tensile Strength of Vertical Plate | 0.14 MPa (The damage was on the PlR) | |

| Thickness | 10-80 mm | |

| Width | 600/1200mm | |

| Dimensional Stability | 0.5/0.9/0.3(length, width and height) | |

Tseason has its own IBIM(Building Information Modeling) Objects, which can provide a crucial and even mandated process to ensure highly efficient and collaborative building planning, design, and construction.