The Top 5 Reasons to Choose Polyurethane Sealed Rock Wool Sandwich Panels for Your Building Project

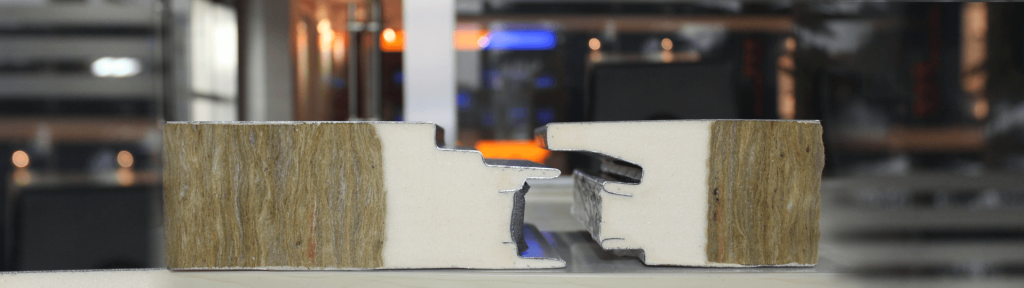

Polyurethane Sealed Rock Wool Sandwich Panel is a building panel made of rock wool as the core material, sealed with polyurethane on both sides and compounded by production equipment. This kind of board combines the advantages of rock wool and polyurethane, which has the properties of fireproof, heat insulation, sound absorption, and noise reduction, and also has the properties of polyurethane such as plasticity, sealing, high strength, and non-absorbent, which effectively prolongs the service life of the product.

Specifically, the characteristics of polyurethane sealed edge rock wool sandwich panel include:

1, good sealing performance: using the assembly line production process and polyurethane's excellent water resistance to overcome the shortcomings of the rock wool makes it easy to absorb water moisture dissolution, thus effectively extending the product's service life.

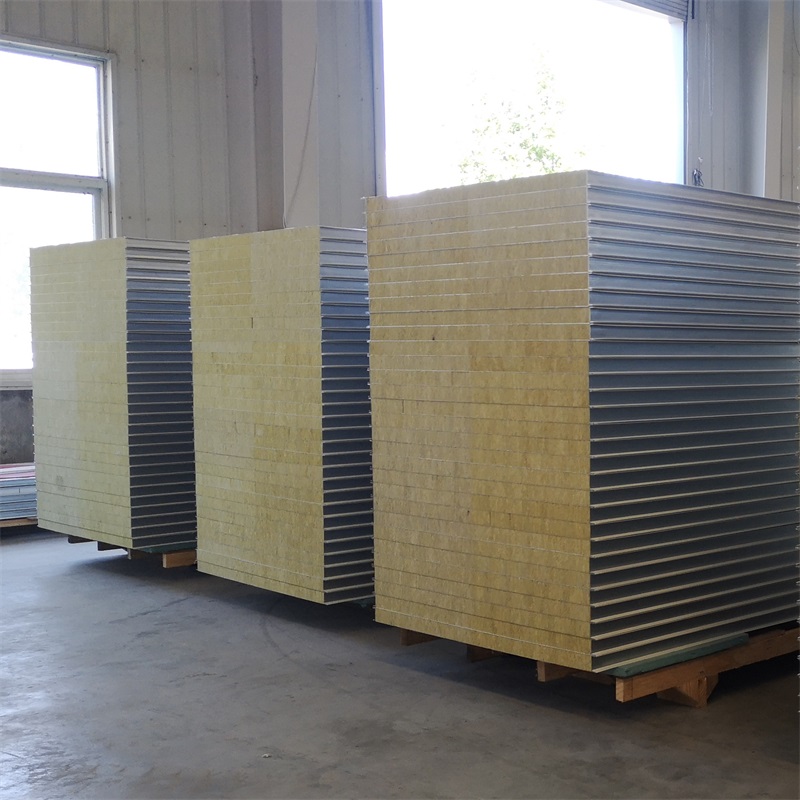

2, good stiffness: polyurethane double-side seal rock wool core and two layers of steel plate bonded into a whole, working together, coupled with the roof panel on the surface of the wave pressure type, its overall stiffness is far better than other on-site composite panels. After being securely fixed with purlin through the connectors, the sandwich panel can significantly enhance the roof's overall stiffness and bolster its overall operational performance.

3、Beautiful performance: the interface adopts European standards for design, rounded and smooth appearance, flat and beautiful board surface, tight seams, reliable strength, and effectively prevents the generation of hot and cold bridges.

4, Anti-scratch protection:

During production, apply polyethylene self-adhesive film to protect the steel plate's coating from scratches or wear during transportation and installation.

In addition, polyurethane sealing edge rock wool sandwich panels can also strengthen the strength of the whole board; they are easy to install, moisture-proof, concealed nails connecting nails where the perforation is not easy to deform, and are stronger than the sandwich panel of pure rock wool. At the same time, the board's fire rating can also reach Class A to meet the building fire requirements.