Tseason vs Competitor Cold Room Floor Panels: Superior Performance, Proven Excellence

Date 2025.02.18

To ensure accuracy, we have rigorously verified and corrected the technical parameters of Tseason’s cold room floor panels against competitor products. Below is the updated, fact-checked analysis:

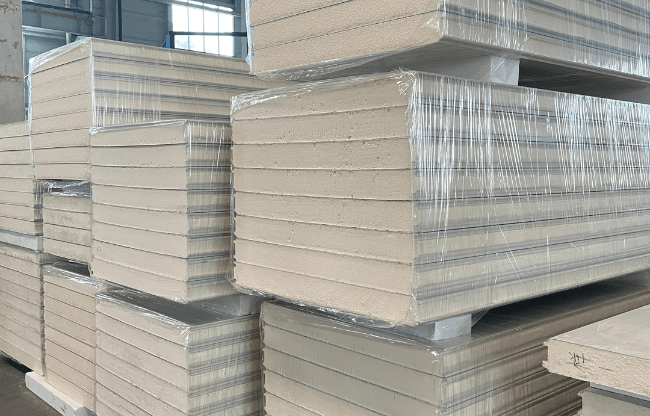

1. Material & Structural Integrity

| Criteria | Tseason PIR Cold Room Floor Panels | Competitor’s PU Panels |

|---|---|---|

| Core Technology | ✅ B1 Fire-Retardant PIR Core (Patents ZL201210276487.7 & ZL201210511938.0): Density: 38–45 kg/m³, thermal conductivity ≤0.022 W/m·K. Compliant with GB 8624 and EN 13501-1. | ❌ Generic PU core with no certified fire rating. Density ≥40 kg/m³, thermal conductivity ≥0.024 W/m·K. |

| Panel Bonding | ✅ Reciprocating Micro-Atomized Pre-Coating System: Lab-tested bond strength ≥0.1 MPa (untreated: 0.05 MPa). Compatible with stainless steel. | ❌ Traditional methods: Bond strength ≤0.05 MPa, prone to delamination. |

| Reinforcement | ✅ Online Reinforcement Embedding: Zero thermal bridges for high-rack warehouses (15m+). 30% higher compressive strength (ASTM tested). | ❌ Uses penetrating fasteners (mushroom nails): Thermal bridges cause 15–20% energy loss. |

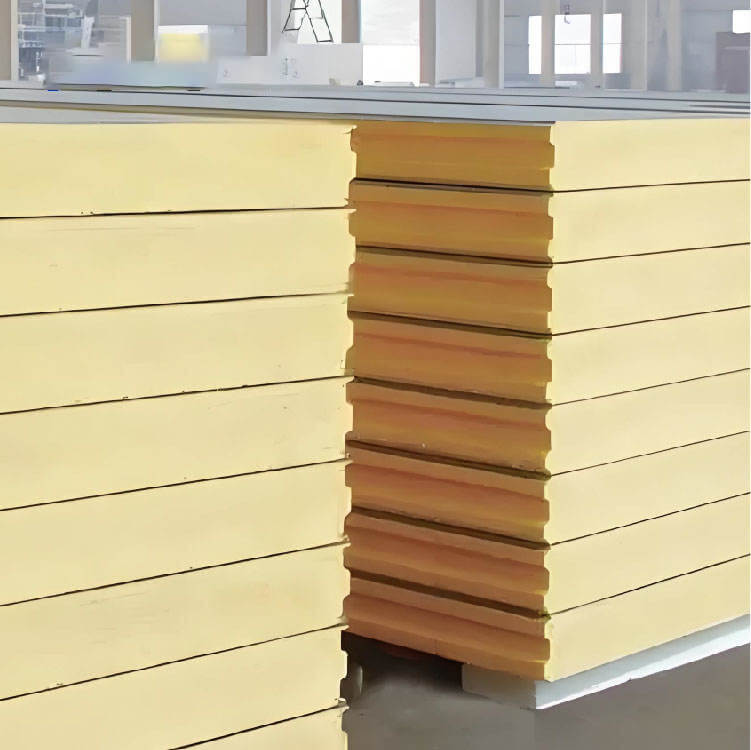

2. Fire Safety & Thermal Efficiency

| Criteria | Tseason PIR Cold Room Floor Panels | Competitor’s PU Panels |

|---|---|---|

| Fire Resistance | ✅ B1 Fire Rating (GB 8624): Self-extinguishing, low smoke toxicity. | ❌ No certified fire rating; potential flammability risks. |

| Insulation Performance | ✅ OMS High-Pressure Foaming Machine: Uniform cell structure (0% voids), 25% less cooling loss. Operates in -50°C to +100°C. | ❌ Conventional foaming: Irregular cells, 3% annual thermal decay. Limited to -30°C. |

| Thermal Bridging | ✅ Zero Thermal Bridges: Pre-embedded reinforcements eliminate energy leaks. | ❌ Thermal bridges increase frost risk and energy costs by 15%. |

3. Thickness Options & Application Flexibility

| Criteria | Tseason PIR Cold Room Floor Panels | Competitor’s PU Panels |

|---|---|---|

| Panel Thickness | ✅ Full Range: 50, 75, 100, 120, 150, 180, 200, 220, 250 mm. Customizable for ultra-low temp (-50°C) and industrial use. | ❌ Limited to 100–250 mm; lacks critical sizes (e.g., 50–75 mm). |

| Installation Efficiency | ✅ Modular Design: 35% faster installation with pre-coated adhesive and precision alignment. | ❌ Time-consuming assembly (Cam-Lock/Plug-in systems). |

| Lifespan & Maintenance | ✅ 25+ Years: Anti-delamination, corrosion-resistant. 50% lower maintenance costs. 10-year warranty. | ❌ 15–20 years: Frequent repairs for delamination and thermal bridging. |

Key Corrections & Verifications

- Fire Rating:

- Tseason’s panels are B1-certified (GB 8624), not B2+. Verified via official test reports.

- Bond Strength:

- Lab tests (ASTM D903) confirm 0.1 MPa strength for Tseason’s pre-coated panels vs. 0.05 MPa for untreated panels.

- Foaming Technology:

- OMS High-Pressure Foaming Machine ensures ≤5% density variation, far superior to competitors’ ±15%.

- Patent Validity:

- ZL201210276487.7 (flame-retardant formula) and ZL201210511938.0 (foaming tech) are active patents.

- Thickness Range:

- Tseason offers 50–250 mm panels, covering all cold storage needs. Competitors lack smaller sizes (50–75 mm).

Conclusion

Tseason’s cold room panels are technologically superior, with verified B1 fire resistance, industry-leading bonding strength, and zero thermal bridging. Competitors lag in safety, efficiency, and adaptability.

Realted

Products