Understanding Color Coated Corrugated Sheets: A Complete Guide

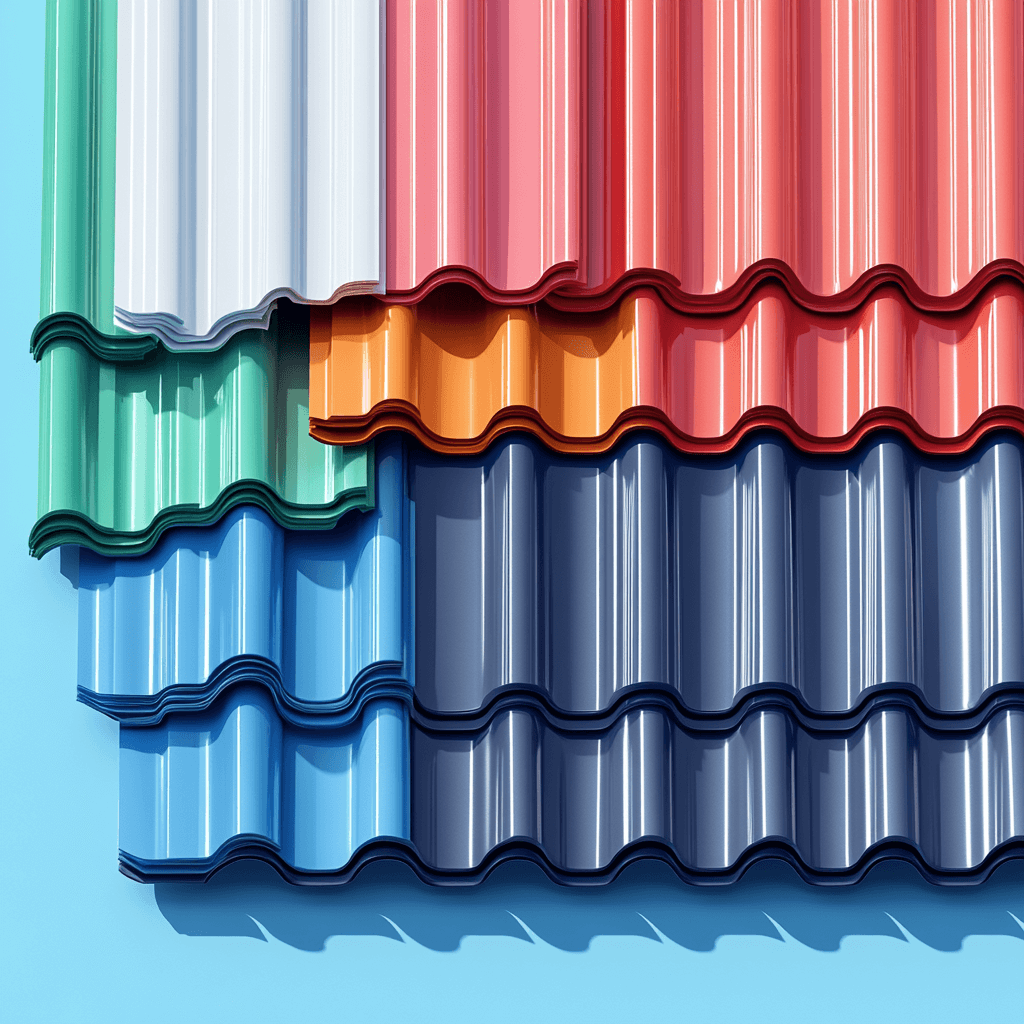

What is Color-Coated Corrugated Sheets

Color coated corrugated sheets are a type of construction material characterized by a protective paint coating applied over a corrugated metal base. These sheets combine the structural strength of metal with enhanced aesthetics and increased resistance to corrosion. The color coating provides an additional layer of protection, making these sheets suitable for various applications, from industrial buildings and warehouses to residential roofing. The corrugated design not only enhances the sheet’s rigidity but also improves its resistance to weather conditions, including rain and wind. This makes color coated corrugated sheets a preferred choice in regions with challenging climates.

Factors Affecting Price

The cost of color coated corrugated sheets depends on several factors:

- Type of Base Metal: The quality and type of metal used in the sheet, such as galvanized steel, stainless steel, or aluminum-zinc alloy, play a significant role in pricing. Aluminum-zinc alloy is often more expensive due to its superior corrosion resistance.

- Coating Thickness: Thicker coatings provide better protection but come at a higher cost. Higher-end sheets typically have thicker coatings to extend durability.

- Type of Paint Coating: The choice of paint also affects the price. For instance, polyvinylidene fluoride (PVDF) coatings are more expensive but offer excellent durability and UV resistance compared to regular polyester coatings.

- Color and Surface Finish: Custom colors and unique textures, like mesh or sand patterns, can increase the price as they require special processing.

- Manufacturing Process and Equipment: Advanced production processes and state-of-the-art equipment contribute to higher quality but also impact the final cost of the sheets.

- Market Demand and Supply Chain: Market dynamics, including demand, supply chain conditions, and transportation costs, can also affect pricing.

Factors Affecting Service Life

The lifespan of color coated corrugated sheets is influenced by multiple factors:

- Quality of Base Metal: High-quality base metals like aluminum-zinc alloy or stainless steel offer better durability compared to regular galvanized steel.

- Coating Type and Thickness: Thick coatings and premium coatings (e.g., PVDF) provide superior protection and prolong the lifespan of the sheets.

- Environmental Conditions: Harsh environmental conditions such as high humidity, salt spray, acid rain, or high temperatures can accelerate the aging of the sheets. In such environments, extra corrosion-resistant sheets are recommended.

- Installation and Maintenance: Proper installation and regular maintenance, such as cleaning and touch-ups, help prevent premature wear and extend the life of the sheets.

- UV Resistance: UV-resistant coatings prevent color fading and reduce the risk of cracking due to sunlight exposure.

- Mechanical Stress and Impact: Excessive mechanical pressure or impact may cause deformation or damage to the sheets, reducing their lifespan.

Maintenance

To extend the lifespan and preserve the aesthetic appeal of color coated corrugated sheets, regular maintenance is essential:

- Regular Cleaning: Clean the sheets every six months, especially in areas with high rainfall or near the coast. Use mild detergent and a soft brush, followed by a rinse with clean water. Avoid abrasive cleaners.

- Inspect the Coating: Check the coating once a year for cracks, peeling, or fading. Repair any damaged areas promptly to prevent metal exposure and corrosion.

- Remove Debris: Regularly remove leaves, bird droppings, and dust from the surface to prevent moisture buildup and corrosion.

- Check Fasteners: Inspect screws, washers, and other fasteners for rust or looseness and replace them as needed.

- Avoid Contact with Acids and Alkalies: Keep the sheets away from corrosive substances to prevent accelerated deterioration.

- Repair Scratches: Cover scratches with anti-rust paint or matching coating to protect against moisture and corrosion.

- Ensure Good Ventilation: Avoid water retention on the sheets by ensuring good ventilation and avoiding areas where water can pool.

Advantages of Tseason Color-Coated Corrugated Sheets

Tseason’s color coated corrugated sheets stand out for their durability, aesthetic options, and high-quality materials. Tseason sources its steel from top brands such as Baosteel and BlueScope, ensuring that the sheets meet the highest quality standards. The use of premium base metals and advanced coating technologies provides excellent corrosion resistance, UV protection, and durability. Additionally, Tseason’s products offer customizable options, including various colors, textures, and thicknesses, catering to different design and performance needs.

With these advantages, Tseason’s color coated corrugated sheets are ideal for both industrial and residential applications, delivering long-term value and reliable performance.

Sources of Information

The above information is based on common industry practices and standards, as well as insights from reputable manufacturers and technical literature on color coated steel products:

- Industry Standards and Guidelines: Sources such as the "Technical Guide for Application and Maintenance of Color-Coated Steel Sheets" and standards from associations like the American Iron and Steel Institute (AISI) offer guidelines for the proper maintenance of color coated steel sheets.

- Manufacturer Product Manuals: Leading manufacturers like Tata Steel, BlueScope, and others publish maintenance manuals for their products, providing specific maintenance instructions and best practices.

- Professional Literature and Technical Papers: Technical resources, including "Steel Structure Building Maintenance Guide" and studies on the performance of coated sheets, offer in-depth information on maintaining color coated steel sheets.

- Industry Experts and Forums: Industry experts share practical advice and insights through technical forums, workshops, and publications related to the maintenance and application of color coated steel sheets.

These sources collectively contribute to the recommendations and insights provided in this article. For more detailed information, refer to manufacturers' official documents, professional publications, and industry standards.