Unlocking the Wonders of PU Sandwich Panels: A Comprehensive Guide

Introduction

In the world of construction, PU sandwich panels have emerged as a revolutionary material, reshaping the way we build structures. This comprehensive guide delves into the intricacies of PU sandwich panels, exploring their composition, advantages, applications, and more.

Understanding PU Sandwich Panels

The Core Composition

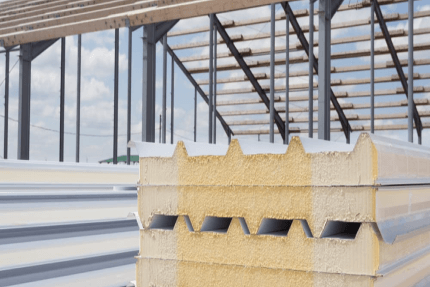

At the heart of a PU sandwich panel lies a unique core made of Polyurethane, a versatile plastic known for its exceptional insulation properties. This core is sandwiched between two outer layers, usually made of steel or aluminum, forming a composite structure.

Unraveling the Versatility

PU sandwich panels stand out for their adaptability. Architects and builders favor them for their ability to cater to various design needs, providing a canvas for creative and intricate architectural solutions.

Advantages that Set PU Sandwich Panels Apart

Insulation Prowess

The standout feature of PU sandwich panels is their excellent insulation capabilities. The Polyurethane core acts as a thermal barrier, ensuring energy efficiency by regulating internal temperatures and reducing reliance on heating and cooling systems.

Strength Meets Lightness

Despite their lightweight nature, PU sandwich panels boast remarkable strength. This characteristic makes them an ideal choice for construction projects where structural integrity is crucial, without compromising on the overall weight of the structure.

Applications Across Industries

Construction Marvels

PU sandwich panels find widespread use in construction projects, serving as the go-to material for walls, roofs, and floors. Their versatility and efficiency in installation make them a favorite among builders aiming for both speed and quality.

Cold Storage Excellence

In the realm of cold storage, PU sandwich panels shine. Their insulation properties make them a preferred choice for maintaining consistent temperature conditions, ensuring the preservation of perishable goods.

Installation: Swift, Seamless, and Precise

Efficiency in Construction

Builders appreciate the efficiency that comes with using PU sandwich panels. Their quick installation not only saves time but also minimizes on-site disruptions, a crucial factor in the fast-paced construction industry.

Precision Fit for Optimal Performance

During installation, the precise fit of PU sandwich panels is paramount. This attention to detail minimizes gaps, ensuring an airtight seal and enhancing overall performance, especially in temperature-controlled environments.

Conclusion: Elevating Construction Standards

In conclusion, PU sandwich panels have elevated construction standards, offering a perfect blend of insulation, strength, and versatility. As the construction industry evolves, the role of PU sandwich panels is set to expand further, contributing to sustainable and energy-efficient building practices.

FAQs: Your Questions Answered

1.Are PU sandwich panels environmentally friendly?

Yes, PU sandwich panels contribute to energy efficiency, reducing the overall environmental impact of a structure.

2.Can PU sandwich panels be customized for unique architectural designs?

Absolutely, the versatility of PU sandwich panels allows for a wide range of customization options to suit specific design needs.

3.How do PU sandwich panels contribute to energy savings?

The exceptional insulation properties of PU sandwich panels reduce the need for excessive heating or cooling, leading to significant energy savings.

4.What is the lifespan of structures built with PU sandwich panels?

With proper installation and maintenance, structures using PU sandwich panels can have a long and durable lifespan.