What Factors Affect the Price of Sandwich Panel Roofs?

Two main factors affect the price of sandwich panel roofs: the facing material and the core material.

Facing Material

Sandwich panel roofs consist of upper and lower metal facings; the material, brand, thickness, and color influence the price.

- The primary influencing factor is the material. Regarding price, stainless steel is preferred over aluminum composite panels > and ordinary steel plates.

- Tseason uses high-end brands for the facings: Baosteel, Bosig, and Yehui. Choosing well-known brand facings ensures better quality and longer service life than ordinary market materials.

- Thickness also impacts the price. The thicker the facing material, the higher the price.

- Additionally, color can affect the price. Non-standard colors require customization, so they are more expensive than standard colors.

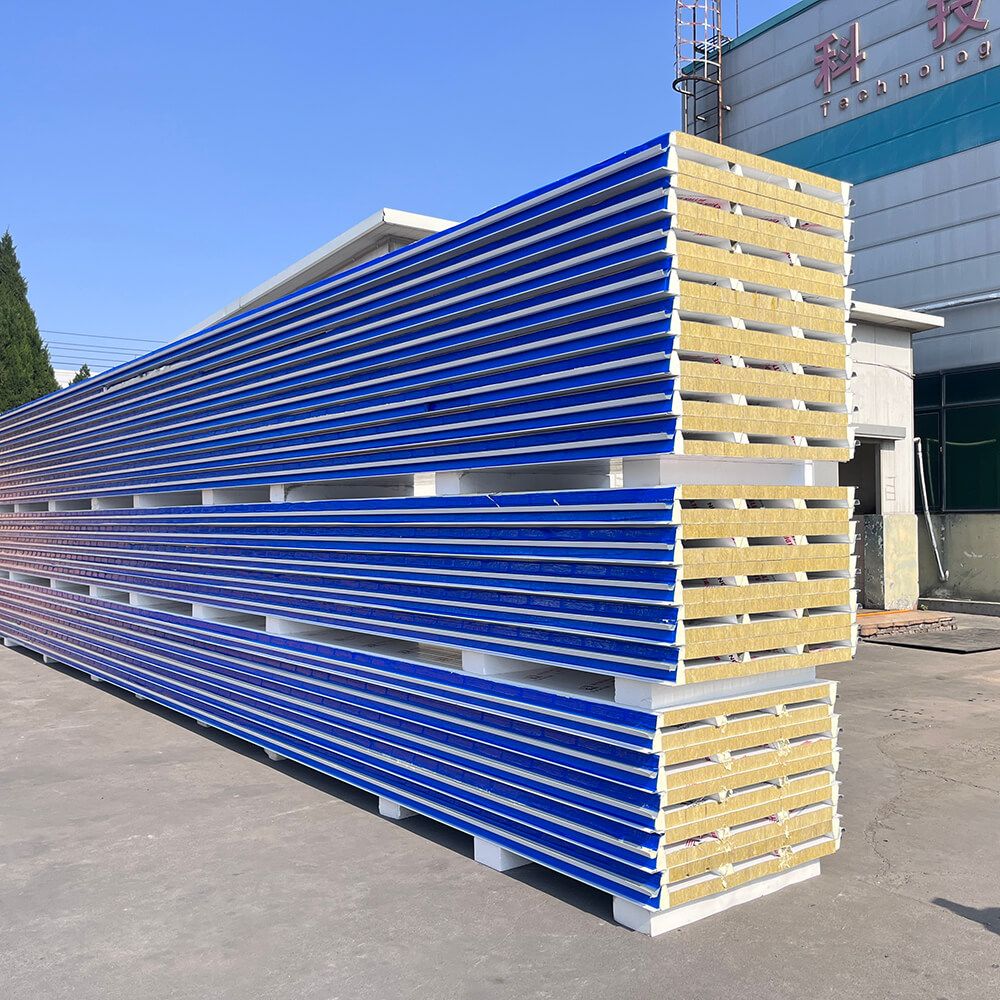

Core Material

The core material in sandwich panel roofs is crucial in determining the price. Tseason offers panels using high-quality materials such as rock wool and polyurethane, each carefully selected for durability and performance.

- Rock wool is crafted from basalt and other natural minerals, melted at high temperatures, and spun into fibers, with binders added to form the final product. Its brand, thickness, density, and fire rating all influence its price. Tseason selects Rockwool from Denmark for its superior durability and stability, ensuring long-lasting performance and fewer maintenance concerns.

- Polyurethane panels from Tseason use black and white materials from top brands like Wanhua, BASF, and Huntsman. By integrating these premium brands, we enhance the fire resistance of our sandwich panel roofs, providing reliable protection.

- Thickness affects pricing for rock wool and polyurethane cores—the higher the cost, the thicker the core.

- Density is another factor. Joint rock wool densities include 80kg/m³, 100kg/m³, and 120kg/m³, with lighter densities being more economical.

- Fire rating is critical, as sandwich panel roofs can reach an A-class fire rating, with higher ratings typically costing more.

Other Influencing Factors

Apart from the material cost itself, other factors also affect the overall project cost.

- Panel Specifications: According to design requirements, shorter panel lengths and more connection points increase costs—both in labor and materials and construction time. Therefore, using relatively longer panels can be more cost-effective while meeting mechanical and wind resistance requirements.

- Application System: Compared to a conventional purlin system, choosing a non-purlin wall system saves on horizontal and vertical purlins and inner lining boards. This reduces the overall steel usage and increases construction efficiency, improving the overall cost-effectiveness.

- Transport Radius: The transport radius refers to the distance a particular product is transported using a specific mode of transportation. The shorter the distance, the lower the cost. Long-distance transport is less economical since sandwich panel roofs are large and heavy. Local sourcing will be more cost-effective.

Tseason's in-house design institute will help optimize your design plans, and our high-quality IBIM (Intelligent Building Information Modeling) system will optimize the design and automatically calculate the material requirements for your project. This approach guarantees high-quality, customized solutions that meet your project’s unique requirements, saving time and reducing overall project costs.