Why Choose Corrugated Metal Roofing for Your Next Project?

Corrugated galvanized metal roofing is becoming increasingly popular in new construction due to its strength and cost-effectiveness. This type of roofing consists of galvanized steel sheets, which are steel coated with zinc to prevent rust. In addition, this type of sheet improves its strength and stiffness, making it possible to use it for many structures. This article further investigates the principles of corrugated sheet metal roofing, including the materials and processes used in its application, highlighting its possible benefits and sustainability. If done correctly, these procedures will help contractors, architects, and even homeowners planning a roofing method to be more sophisticated when choosing this popular and widely adopted modern method.

What are the main benefits of using corrugated metal roofing?

One of the main factors when choosing clamping metal roofing sheets on a building is that they are very durable, thanks to the galvanized coating that prevents oxidation. In addition, these roofing systems are relatively lightweight, which helps reduce structural loading requirements, and, therefore, are easy to install. In addition, they are cost-effective in the long term due to minimal maintenance requirements and a durability of over 30 years. The metal support of the roof contributes to energy efficiency, as heat is not absorbed into the building but radiated away, thus reducing cooling costs for the building. Finally, these roofs are not harmful to the environment, as they can be recycled, and a large proportion of the materials used can be recycled.

Why choose a corrugated roof for your project?

A corrugated roof is the best choice because it is resistant to adverse weather conditions and can be used for a long time with low maintenance. It is also lightweight, making installing and placing minimal loads easier. In addition, the material is energy-saving and recyclable, contributing to green building. It is, therefore, suitable for any project that requires a balance of durability and environmental friendliness.

Long-term durability of corrugated galvanized steel

Long-term temperature resistance of corrugated galvanized steel Galvanized steel is impressive because of its structure and design. The steel sheets are physically stronger thanks to the iron ends, while the zinc coating theoretically prevents the steel from rusting over time. This combination helps the roofing material withstand extreme weather, such as heavy rain, strong winds, and snow loads, thereby maintaining structural integrity for decades. Moreover, it maintains its properties at high and low temperatures, extending its lifespan and making it a good choice for roofing.

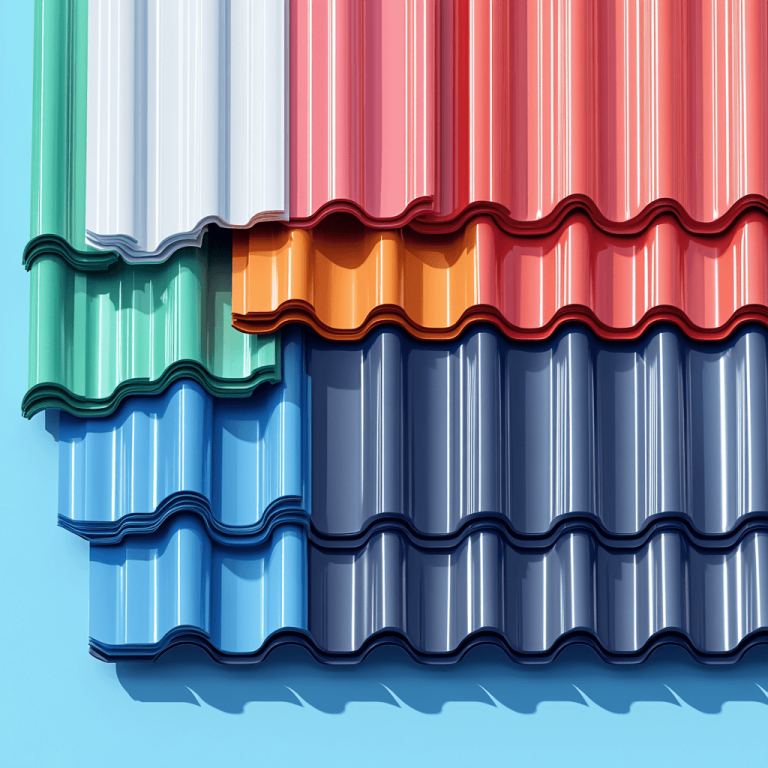

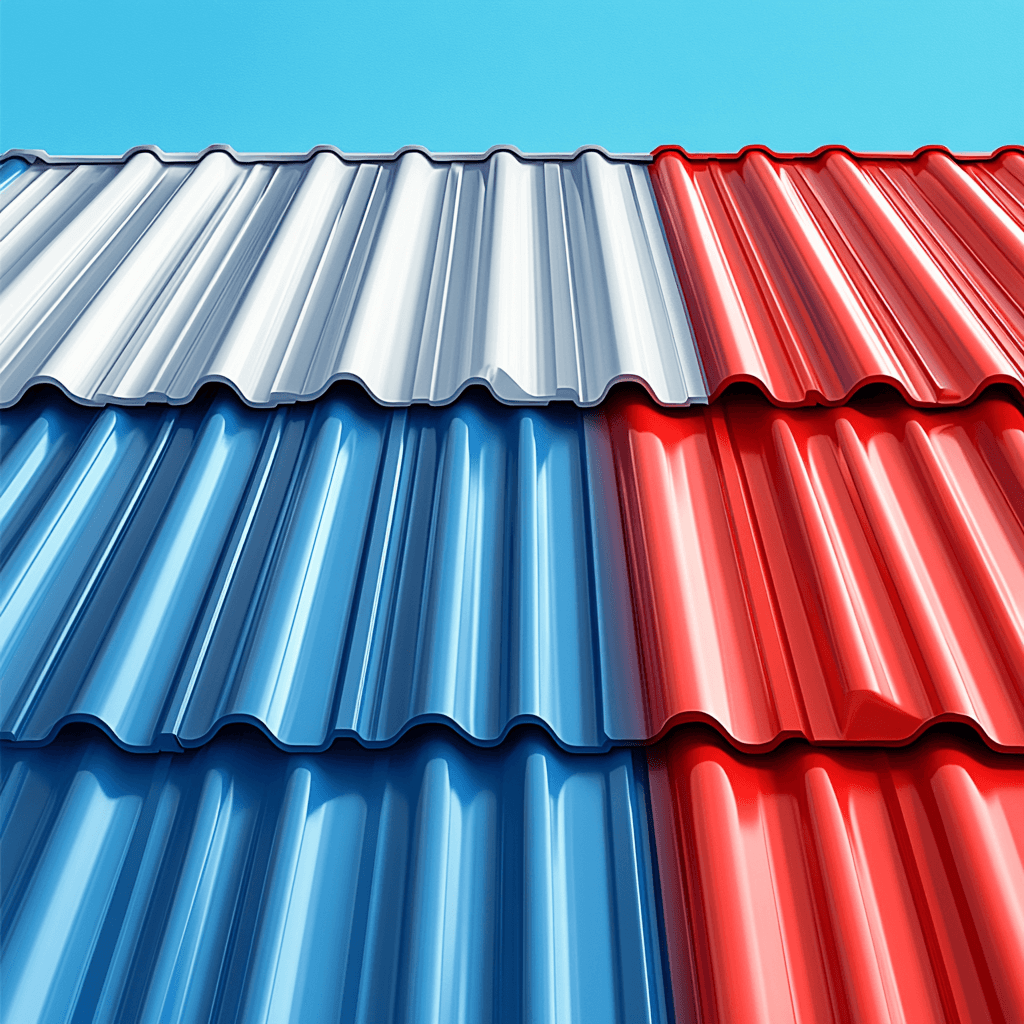

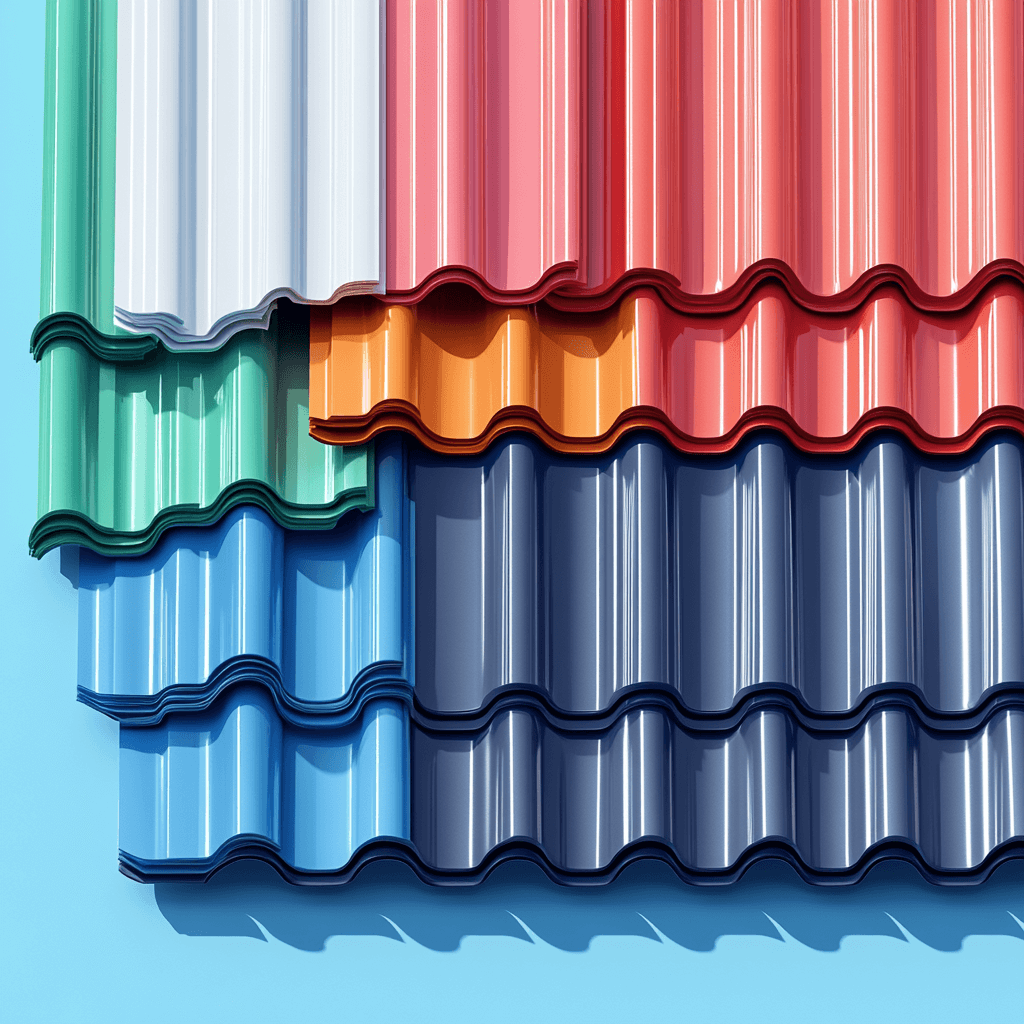

The aesthetic appeal of corrugated metal sheets

Due to their modern, industrial design, corrugated metal sheets can be integrated into almost any architectural design. The panels are available in different materials, finishes, and colors, which makes it possible to design both traditional and modern environments. Their distinctive wave patterns also provide texture and visual interest to any structure that incorporates them. The trend here even includes enhancing the effectiveness of such structures, which, at least so far, are used to design modern and bold exteriors or their focal details. Some finishes can reflect light, which explains the design's enhancement of natural light and brings about charming spaces that are likely to impress.

How is a galvanized steel roof installed?

A step-by-step installation process for a galvanized corrugated roof

- Preparation and measurement: First, the number of panels installed on the roof must be accurately assessed. In addition, it must be confirmed that the roof structure is tidy, dry, and stable enough for installation.

- Panel cutting: The corrugated metal sheets are cut to size using the appropriate tools. As a general rule, safety measures are taken to prevent accidents.

- Underlay installation: The waterproof underlay is fully unrolled and laid on the roof's initial underlay surface. It is loosely placed to prevent moisture from entering.

- Panel placement: Place the first panel from the roof's lower edge. Ensure the edges overlap and each panel is correctly aligned to provide weather protection.

- Fixing the panels: The roof covering panels are fixed to the longitudinal beams with galvanized screws. The spacing technique is median, i.e., along the length of the corrugations, i.e., on the longitudinal ridges outside the enclosure.

- Roof ridge cap installation: Roof ridge caps are used at the top of the roof where the panels meet to form vertical seams. The caps are again secured in place using the screws provided.

- Edge treatment: Finally, the outer edges of the panels are properly covered and sealed using edge flashing. This helps prevent water penetration and enhances the roof's aesthetics.

- Ensure that all panels and accessories are correctly secured and that no loose elements could cause leaks.

Essential tools and materials for roof panel installation

A manufacturer-recommended tool kit is essential to install corrugated metal roof panels. The required tools include a measuring tape, cutting tools (e.g., circular saw and metal shears), and simple fastening tools (e.g., drill or screwdriver). In addition, personal protective equipment (PPE) such as gloves, goggles, and other fall protection equipment must be used during installation. The primary materials needed are corrugated metal sheets, galvanized screws, a water-resistant liner, ridge caps, and edge flashing. Ensuring that these tools and materials are readily available will make the installation process more efficient and ensure that the quality of the work remains high.

Common mistakes to avoid during the installation of a steel roof

- Measurement complications: One of the most common mistakes when installing a steel roof system is over-exposure and overestimating the roof area. Correct measurements are crucial to eliminate waste and enable the panels to be installed seamlessly.

- Improper fastening: An unstable roof can also result from improper fastening of the metal panels. Specific instructions should be followed regarding the placement of screws, and fasteners should be used to fix the panels in place securely.

- Lack of proper ventilation: If adequate ventilation is not provided, moisture can accumulate on the roof, causing corrosion and wear to the metal. Integrating sufficient ventilation during installation will help extend the roof's lifespan.

What types of corrugated sheets are at Tseason?

Different profiles of corrugated metal sheets

Corrugated metal sheets come in different profiles, including the following:

- U-panel: This type of sheet has an older architectural style, as it has deep grooves and is common in homes.

- R-panel: This type consists of shallow corrugations, giving a modern look suitable for homes and offices.

- 5V-press: Consists of protruding V-shaped tabs and has a classic appearance. This is common in rural and farm applications.

- Box profile: These edges are broader than those flush with the ribs, so they have a flatter edge and, therefore, a very modern and robust appearance, suitable for industrial and agricultural structures.

- Standing seam: This refers to the presence of fasteners on vertical panels that can be transported and form a stampable structure. It is very common when constructing complex structures.

Choosing the right galvanized sheet thickness

Choosing the right galvanized sheet thickness depends on several issues, such as its use, the product, and structural considerations. In residential use, a thickness of 29 to 26 gauge is usually more than sufficient, providing the sheet with enough strength and is cost-effective. For commercial and industrial use, a stronger sheet of 24 to 20 gauge may be required to withstand greater loads and more extreme conditions. It is crucial to assess the performance requirements of the roofing solution, focusing on the immediate environment, including the weather, exposure to corrosive elements, and any other loads it is subjected to, to achieve the desired level of perfection and longevity.

Galvanized corrugated roofing sheets compared to other materials

Here’s a revised version of the paragraph with improved readability:

Several key factors must be considered when comparing galvanized corrugated roofing sheets to other materials, including durability, cost, and environmental impact. One of the standout features of galvanized sheets is their corrosion resistance, thanks to the protective zinc coating, making them particularly suitable for humid environments. While these sheets may have a higher upfront cost, they offer long-term savings due to lower maintenance needs and are generally more durable than asphalt shingles.

In contrast, clay tiles offer a unique aesthetic appeal but are more expensive and often used for their earth-based properties. Aluminum roofs, known for their corrosion resistance, are similar to galvanized steel sheets but lack the full strength of steel, making them more vulnerable to damage from severe weather.

Each material has advantages and drawbacks, so the choice ultimately depends on specific project needs, budget, and preferences.

How do you maintain your corrugated galvanized roof?

Tips for regular maintenance of your galvanized metal roof

- Annual inspection: Check at least once a year for rust, wear, or damage. Also, check for loose or missing screws and tighten as necessary.

- Regular cleaning: Regular removal of debris, leaves, and dirt that accumulate on flat roofs is essential to prevent the build-up of moisture that can corrode the roof.

- Tackle rust at a good time: Applying anti-corrosion paint at a good time is necessary for dealing with such defects and should be done before the damage spreads.

- Check sealants and waterproofing: Sealants and waterproofing should be inspected regularly for wear and tear and repaired or replaced to maintain the building's waterproofing.

- Trim overhanging branches: Trees close should be pruned, as their branches or debris are likely to fall and cause damage in a storm.

- Monitor leaks: The wall structure has problems; leaks must be detected quickly, and the damaged or affected parts must be repaired.

Identify and repair damage to corrugated metal roofs.

When inspecting a corrugated metal roof, the first thing to check is whether it is damaged. If signs of dents, perforations, or roof panels have come loose, they should be cut and covered where there are no seams. It would help if you also looked at areas where the layers of corrugated sheets overlap, as these are prone to leaks or corrosion due to pressure when the structure is built. It would help if you also looked out for rust on the surface, especially around the edges and fasteners. Once you notice damage to the roof, take precautions to replace broken screws, plug/use caulk to fill small holes or use paint to prevent exposed metal from rusting. However, if the damage is more severe than expected, replacing the entire panel or part of it may be necessary to prevent the roof cladding from sagging and keep it waterproof.

Extend the life of a galvanized steel roof.

Some regular and preventive work must be carried out to ensure that a galvanized steel roof lasts as long as possible. First, the roof must be maintained; buckets and gutters must be regularly cleaned to prevent water from pooling and causing rust. Remember to check the roof for fasteners and other possible leaks occasionally. Use metal paint or cladding to limit the effects of bad weather on the roof of the building. In addition, limit exposure to overhanging tree branches and unnecessary vegetation and further improve the drainage system to prevent water from pooling. If you always pay attention to these factors, it is possible to extend the life of a galvanized steel roof so that it can both function and remain beautiful.